As industrial and production activities increase, the management of hazardous waste has become an urgent challenge. These include various flammable, corrosive, reactive, infectious, and toxic wastes along with their mixed counterparts. Scientifically treating hazardous waste not only helps mitigate their impact on the environment and human health but sometimes also enables the recovery of valuable materials for resource reuse.

The handling of hazardous waste typically occurs within enclosed environments to prevent hazardous spread. It generally involves two stages: pre-treatment and neutralization(Optional). Pre-treatment is aimed at sizing hazardous waste for subsequent steps, commonly involving shredding, mixing, and pumping; Neutralization, on the other hand, aims to thoroughly destroy the waste or eliminate harmful components, utilizing processes like incineration, cement kiln co-processing, and high-temperature sterilization.

At GEP ECOTECH, we offer tailored solutions for various types of hazardous waste. We collaborate closely with our clients, striving to provide efficient, safe, and compliant waste management methods.

Hazardous Waste Recycling

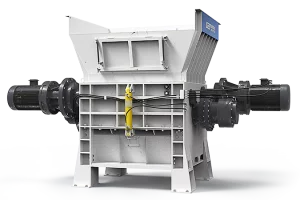

Some hazardous waste recycling processes are straightforward, requiring only preprocessing for recycling. However, there is a high risk of leaks or explosions during the handling process, necessitating the use of special facilities, typically closed systems, to ensure safety. For example, metal paint drums, chemical bulk bags, IBC totes, lead-acid batteries and other materials are favored by many recyclers due to their high recycling value and simple process.

GEP ECOTECH has amassed extensive experience in hazardous waste resource recovery solutions. Our enclosed shredding systems have been utilized across various hazardous waste recycling domains. The company is consistently committed to streamlining the recycling process, offering efficient and reliable resource recovery solutions to recyclers.

Cement Kiln Co-processing

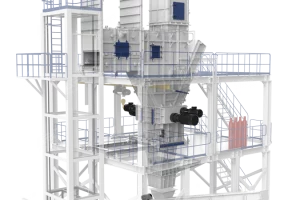

Cement kiln co-processing of waste is a highly matured process that utilizes high-temperature waste destruction during the clinker manufacturing process. Incinerating combustible materials can also provide heat for the cement kiln. The low-ash residue post-incineration can serve as raw material for cement production, simultaneously solidifying heavy metals within it, preventing their leakage into the environment.

GEP ECOTECH offers safe, reliable, and flexible solutions for the co-processing of hazardous waste in cement kilns. Collaborating closely with cement companies, we design unique preprocessing systems, such as Shredding-Mixing-Pumping or other modified versions, tailored to the characteristics of each cement plant.

Incineration

While controversial in certain countries, incineration remains one of the most prevalent methods for disposing of hazardous waste.. This method can utilize existing incineration facilities, and the heat generated by incineration can also drive steam turbines to generate electricity (Waste-to-engery). Incineration has obvious benefits in treating certain hazardous wastes, such as clinical wastes, as high temperatures can destroy pathogens and toxic substances. Municipal solid waste treatment in many countries also relies on incineration technology.

GEP ECOTECH has provided solutions for numerous waste incineration centers, actively engaging in the construction and operation of these projects. Leveraging our extensive experience, we can offer invaluable insights to your project, aiding in risk mitigation. Beyond equipment provision, our primary focus is supporting the smooth progression of your project.

Inactivation or Disinfection

Inactivation or disinfection is commonly used for the destruction or recovery of medical waste, primarily aimed at eliminating pathogens to prevent infection or environmental contamination. This process is often achieved using methods such as high-temperature steam or microwaves. The material treated through deactivation no longer possesses infectivity and can be disposed of following standard solid waste treatment procedures.

GEP ECOTECH offers a variety of flexible solutions for biohazardous waste disposal, ensuring the safe management of these materials while also facilitating the recovery of valuable resources.