The global clothing and fashion industry generates nearly 100 million tons of waste every year, which comes from scraps or remnants of the production process (pre-consumer), as well as clothing and home textiles discarded by people (post-consumer). These waste materials vary, including various natural cotton and linen, chemical fibers, leather, etc. In many places, they are not properly disposed of and are simply landfilled, posing huge risks to the environment.

The recycling of textile waste can be divided into several categories according to the pyramid model:

How Can GEP ECOTECH help Recycling Textile Waste

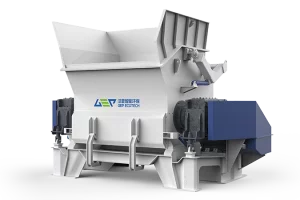

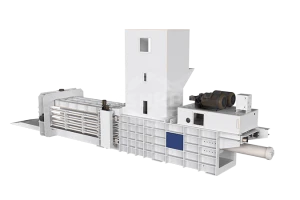

GEP ECOTECH provides a complete set of equipment for textile fiber recycling and alternative fuel production, and we design production line configurations based on actual requirements. The waste textile recycling equipment offered by GEP ECOTECH includes conveying equipment, shredders, various separation machine, fine grinders, pelletizers, balers, and more. Our equipment is designed for long-duration, high-volume industrial scenarios, with a maximum recycling capacity of up to 30 tons per hour.

The industrial shredder is the core equipment in the textile recycling system, as efficiently shredding a large amount of fabric requires equipment that delivers unparalleled cutting force while ensuring output size and operating in an environment with ultra-low noise and dust. Our various shredder combinations ensure that your recycling application operates at the best discharge size, optimal energy efficiency, and lowest wear.