Explore GEP ECOTECH for the Latest Updates on Our Developments

Recently, we received exciting news from our South Korean customer: the GD9Q dual-shaft shredder we supplied has been…

Jul 12, 2024

Tire shredders, also known as tire crushers or tire granulators, are used to reduce tires into smaller pieces, often as part of…

Mar 29, 2024

With the continuous development of industrialization, the disposal of scrap metal has gradually attracted people's attention.…

Jan 25, 2024

With the continuous development of agricultural production, the recycling of rural biomass straw has attracted more and more…

Jan 24, 2024

The cement industry is undergoing a positive and remarkable transformation: replacing fossil fuels with refuse derived fuels (…

Jan 3, 2024

GEP ECOTECH has been committed to manufacturing shredding systems for medical waste since 2013.Our shredders serve over 20…

Dec 15, 2023

In today's market, maintaining brand integrity is crucial for businesses. One effective way to ensure that branded garments, especially those that are defective, outdated, or unsellable, do not re-enter the market is by using specialized shredding machines. These machines are designed to securely destroy branded…

Oily rags are a hazardous waste, proper disposal of oily rags is essential for industrial safety and compliance. Depending on the volume of oily rags generated, different shredding solutions may be appropriate. This article introduces two types of oily rag shredder machines available for sale: the dual-shaft linear…

Against the backdrop of the rapid development of modern industry, the generation of hazardous wastes has shown an explosive growth trend. These hazardous wastes are not only diverse, but also complex in nature, covering a wide range of hazardous characteristics such as radioactivity, infectiousness, corrosiveness,…

Recently, we received exciting news from our South Korean customer: the GD9Q dual-shaft shredder we supplied has been officially put into operation for scrap metal shredding.The customer, a prominent metal recycling company, handles a variety of scrap metals, including copper-clad laminate, circuit boards, copper-…

The disposal of waste iron barrels has long plagued the industry and waste management departments, but with the increased awareness of resource recycling and technological advances, waste iron barrels shredding projects are gradually becoming an effective way to solve this problem. Economic Analysis and Capital Investm…

Flexible Intermediate Bulk Containers (FIBC) bags are a globally recognized solution for bulk material handling. Unlike standard woven bags, they typically hold 1000L and offer superior load capacity and durability. Widely used in industries such as chemicals, mining, and food, FIBC bags come in various types for…

In the booming development of the wind power industry, wind turbine blades, as core components, have attracted much attention in their production, use, and disposal. The wind turbine blade shredder, as a key equipment for handling wind turbine blade waste, is gradually occupying an important position in the industry.…

Innovative highlights of scrap metal shredders Scrap Metal Shredder, a machinery and equipment designed for converting waste metals into small pieces of materials that are easy to manage and reuse. It plays an irreplaceable role in many metal recycling processes, such as scrap iron and steel, scrap non-ferrous metals…

The production of palm oil in Central and South America and Southeast Asia is an important industry. After the brown ripens, the fruit separates from the stem, leaving an empty fruit bunch (EFB) as a waste. Every year, tens of millions of tons of EFB are generated, and research on the possibility of utilizing this…

With the advancement of technologies such as electric vehicles and battery energy storage, the lithium-ion battery market is experiencing rapid growth. Given the increasing demand for cobalt and lithium in the production of these batteries, their prices are rising. Recycling materials from retired batteries is more…

Recently, we often receive inquiries from customers who want to choose a shredder for jumbo bag. Many customers don't know what equipment to use. Today, let's talk about what equipment to use for crushing jumbo bag.What are Jumbo Bags?Jumbo bags are flexible transport packaging containers known for their advantages…

With growing environmental concerns and the pressing need for sustainable practices, the metal recycling industry in Australia is witnessing significant advancements. Efficient and robust metal recycling equipment is pivotal in meeting the increasing demand for metal recovery and processing. This article explores the…

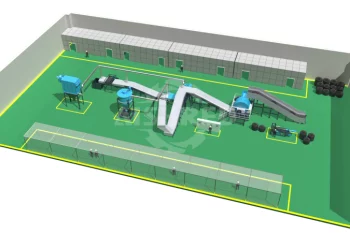

AI Shred's ingeniously designed intelligent household waste treatment system integrates advanced technology and environmental protection concepts, aiming to achieve effective resource conversion of urban waste through refined processing processes. The system is carefully configured with core components such as feed…

With the rapid development of social economy, people's quality of life is constantly improving, but the amount of domestic waste is also on the rise, so the treatment of domestic waste has become extremely critical. The treatment of domestic waste is based on environmental, health and resource pressures, and its…

Industrial waste is composed of waste generated during the industrial production process, which can be in the form of solid, liquid, or gas. The industrial waste we usually refer to mainly refers to industrial solid waste. These industrial wastes need to be properly treated to reduce their impact on the environment…

In modern society, with the growth of population and the change of consumption patterns, the amount of domestic waste is increasing, which brings great challenges to urban environment and resource management. Traditional garbage disposal methods, such as landfill and incineration, not only occupy a lot of land…

In agricultural production, crop straw is a rich and renewable resource. However, the comprehensive utilization of crop straw has been a difficult problem for a long time. With the continuous development of science and technology, the emergence of straw shredders provides an effective way to solve this problem.The…

Normally, heavy materials such as broken bricks and concrete in c&d scrap are crushed and sorted into recycled aggregates and reused in the construction and building materials industry to achieve resource utilization. However, light materials such as wood chips, paper, cloth, and plastic are piled up and left idle…

Biomass straw pretreatment technology is an important preliminary step to convert the remaining straw after crop harvest (such as the stalks of crops such as corn, wheat, and rice) into energy or other high-value products. This technology changes the physical and chemical properties of the straw through physical,…

Solid radioactive waste (SRW) poses significant challenges in terms of its safe management and disposal. To address these challenges, advanced shredder technology has emerged as a crucial tool for grinding and homogenizing SRW.Understanding Solid Radioactive Waste (SRW)SRW encompasses various materials contaminated…

The recycling industry faces unique challenges in processing thick polyethylene (PE) slabs, particularly those measuring 15 centimeters in thickness. This article delves into the complexities of shredding 15cm thick PE slabs and explores suitable shredder models designed to overcome these challenges. Challenges in…

Medical waste is a type of solid waste that must be properly managed because it contains potentially infectious microorganisms and has specific characteristics. The World Health Organization, as well as various countries and regions, have established strict disposal guidelines and regulations for medical waste based…

With the development of the global economy, the market demand for waste aluminum recycling industry will gradually increase. At the same time, with the development of technology, the technology of waste aluminum recycling will continue to innovate, bringing more opportunities and challenges to the development of the…

Biomedical waste, including sharps, infectious materials, and chemical waste generated from healthcare facilities, poses significant environmental and public health risks if not managed properly. In recent years, advancements in technology have spurred the development of innovative treatment and disposal methods to…