In contemporary industrial production, the significance of resource recycling and reuse is becoming increasingly evident, with the efficient crushing treatment of scrap aluminum castings being one of the crucial links. However, traditional crushing equipment often struggles to balance the crushing effect and space limitations. Especially when facing specific demands, achieving the desired crushing effect within limited space has become an urgent problem to be solved.

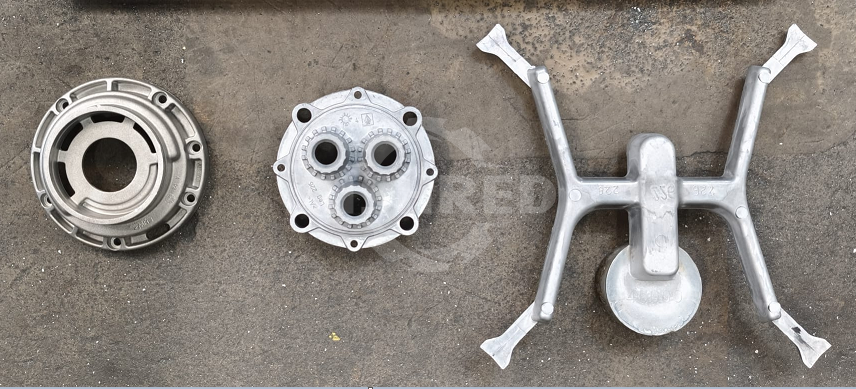

Recently, a customer in Germany encountered such a dilemma. They needed to crush scrap aluminum castings to a size of less than 100 mm to meet the requirements of the subsequent production process. But due to the limited space available, they could not adopt the traditional solution of using two separate devices for crushing and screening in series. The customer was in urgent need of a solution that could complete the shredding process and achieve the desired size on a single device.

In response to this demand, GEP ECOTECH has proposed an innovative integrated drum screen shredder solution. This device integrates the functions of crushing and screening into one unit. Through unique structural design and precise process parameter control, it can efficiently shred scrap aluminum castings on a single device and ensure that the output material size remains stable at less than 100 mm. This solution not only meets the customer's size requirements but also effectively addresses the space limitation issue.

Integrated Drum Screen Shredder Advantages:

Lower Cost

Reduces equipment investment by eliminating the need for additional screening equipment. It also lowers energy consumption and maintenance costs, providing an economical solution for customers.

Higher Efficiency

The integrated design simplifies the production process by reducing material transfer steps, thereby increasing production efficiency and ensuring a smooth production process.

Smaller Footprint

A single device can complete both crushing and screening, saving space. It is particularly suitable for customers with limited space and maximizes the use of existing space.

More Stable Shredding Effect

Through optimized design, it ensures uniform output material size, meeting the customer's production requirements and improving the quality of the final product.

Easier Operation

Equipped with an intelligent control system, it features a user-friendly interface that is easy to operate and maintain, reducing the difficulty of operation.

GEP ECOTECH has always been committed to providing personalized customized solutions for customers. We understand that each customer's needs are unique. Therefore, we can tailor the most suitable equipment and processes according to the actual needs of our customers. Whether it is crushing, screening, or other environmental protection equipment, we can offer personalized customization services to help customers optimize their production processes, reduce costs, and improve efficiency.

If you have any customization needs, please feel free to contact GEP ECOTECH. We will provide you with a professional customized solution to meet your requirements.