Lithium batteries have become an indispensable energy carrier in modern life, powering everything from electric vehicles to mobile devices. However, as these batteries reach the end of their service life, the volume of retired units continues to grow substantially. While recycling these batteries offers significant economic potential, it also presents serious challenges—including safety hazards, low recovery efficiency, and environmental risks throughout the process.

Black Mass: The Core of Battery Recycling Value

The industry's focus is increasingly centered on Black Mass – a concentrated intermediate powder recovered from end-of-life lithium batteries, primarily composed of cathode and anode active materials rich in strategic metals such as lithium, nickel, cobalt, and manganese.

This high-value material is typically produced through a sequence of pretreatment, shredding, pyrolysis, and milling processes, followed by physical separation to remove casing metals. As a key intermediate, black mass provides a standardized, high-value feedstock for subsequent resource recovery processes. Through appropriate metallurgical routes—such as hydrometallurgy, pyrometallurgy, or combined approaches—it can be efficiently processed to extract valuable metal components including lithium, nickel, cobalt, and manganese. These are then refined into battery-grade materials such as lithium carbonate, nickel sulfate, and cobalt sulfate, enabling the return of critical resources to the new battery manufacturing chain. The consistency and quality of black mass directly influence the efficiency, cost, and environmental footprint of these downstream recovery operations.

GEP ECOTECH's Integrated Solution: From Whole Batteries to Mixed Black Mass

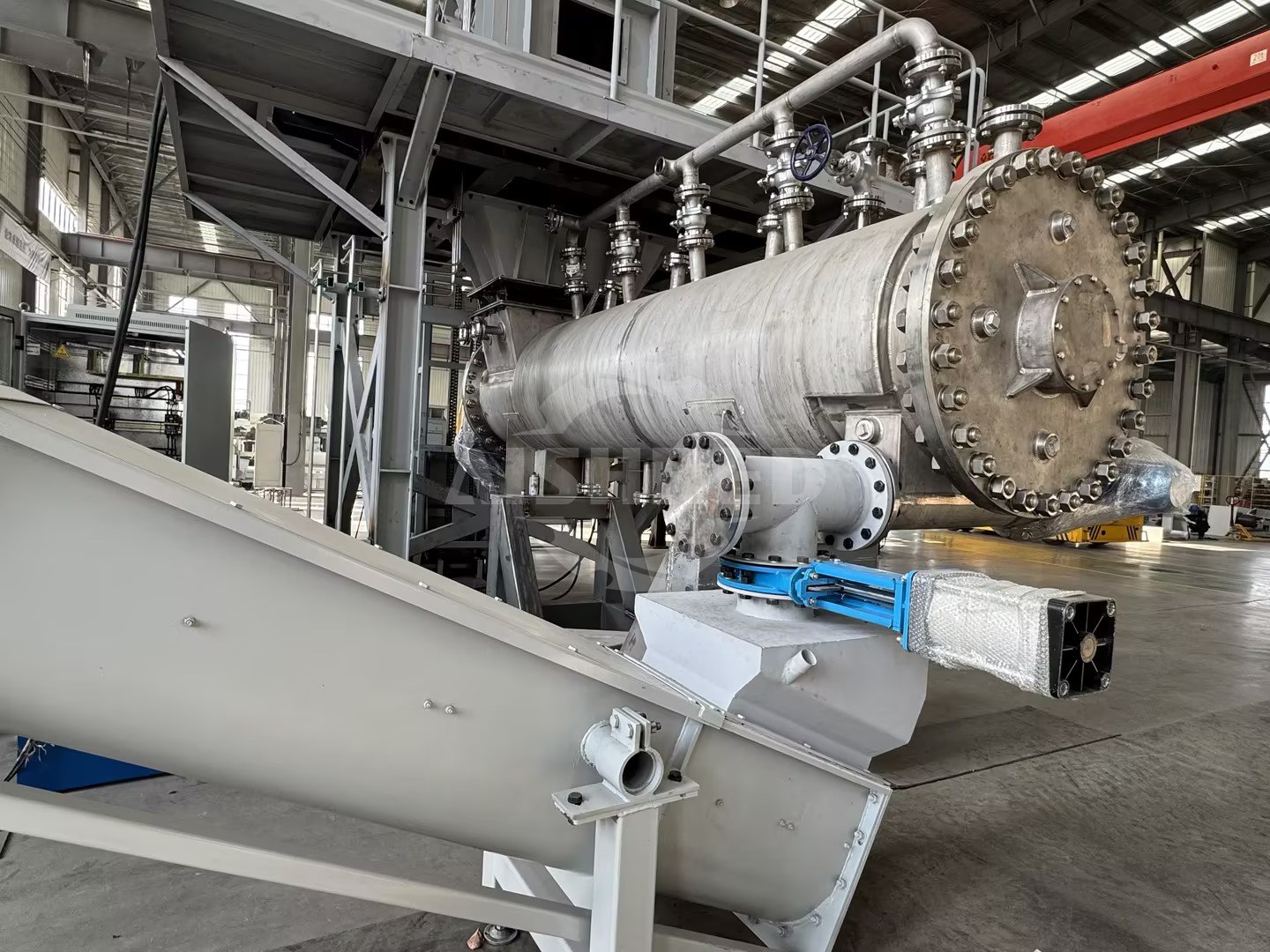

GEP ECOTECH provides a full-chain integrated solution that transforms whole waste batteries into mixed black mass. Our capability is demonstrated through practical implementations, including a recent pilot-scale lithium battery recycling line delivered to a customer in Latin America. This project exemplifies our ability to support clients from initial testing phases through to full-scale commercial operation, covering the main workflow, ensuring safety, efficiency, and output quality.

The system begins with safety-focused Pre-treatment before material enters the Closed Shredding System. Featuring a sealed, nitrogen-inerted design, the battery shredder system prevents fire and explosion risks during shredding. The shredded material is then processed through a Vacuum Pyrolysis Furnace to decompose organics and liberate electrode materials. Subsequent steps include fine grinding via a Hammer Mill and separation of residual metals, ultimately yielding high-purity mixed black mass for closed-loop battery production.

System Value: An Integrated Chain for Maximum Return

The "Pre-treatment + Shredding + Pyrolysis + Separation" process represents a deeply synergistic, integrated system. GEP ECOTECH's full-chain solution eliminates safety hazards at the source, controls environmental risks throughout, and ensures the final mixed black mass output is of exceptional quality—characterized by high valuable metal content, uniform particle size, and optimal chemical reactivity. This precise coordination across all stages delivers significant and stable economic returns for our clients.

Choosing a professional and reliable integrated solution is key to successfully tapping into the lithium battery "urban mine". GEP ECOTECH's full chain battery recycling system, which can transform waste batteries into high-value black mass, empowers clients to capture the full value of the circular economy and excel at the high end of the industry value chain.