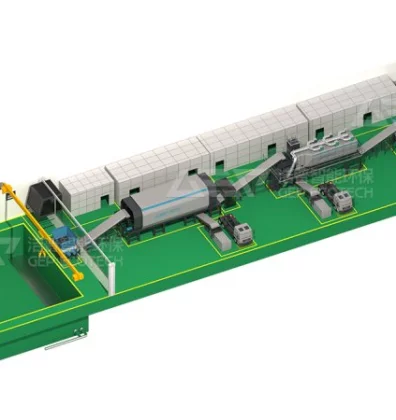

In today's plastic recycling industry, especially when dealing with Low-Density Polyethylene (LDPE) film scrap, the right shredding equipment determines not just efficiency but also profitability. LDPE films are notoriously difficult to process—thin, flexible, and often contaminated—making them a challenge for recyclers worldwide. A high-performance shredder breaks down bulky film waste into manageable, uniform pieces, ensuring smooth feeding for subsequent washing, granulating, and pelletizing. This first step is critical to transforming problematic plastic waste into a valuable secondary resource.

To meet different recycling needs, a variety of shredding solutions are available. Single-shaft shredders deliver cost-effective size reduction, while dual-shaft models provide higher throughput and stronger cutting power. For demanding operations, quad-shaft shredders offer unmatched precision and reliability, minimizing downtime and maximizing recovery rates. By choosing the right machine, recyclers can cut costs, boost efficiency, and position themselves at the forefront of sustainable plastic waste management.

Single-Shaft Shredders

- Overview: Single-shaft shredders are fundamental in LDPE film scrap recycling. They feature a single rotating shaft equipped with robust blades designed to cut, tear, and shear the material into smaller pieces.

- Advantages: The output size is smaller, cost-effectiveness, and versatility for general plastic shredding applications.

Dual-Shaft Shredders

- Overview: Dual-shaft shredders elevate shredding efficiency with two interlocking shafts, each equipped with blades. This configuration provides a more controlled and thorough shredding process for LDPE film scrap.

- Advantages: Enhanced throughput capacity, improved particle size consistency, and versatility for various plastic materials.

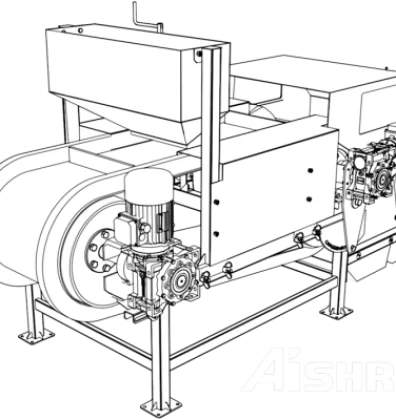

Quad-Shaft Shredders

- Overview: Quad-shaft shredders take efficiency to the next level with four interwoven shafts featuring cutting blades. This configuration offers unparalleled cutting power and precision for processing LDPE film scrap.

- Advantages: Exceptional cutting performance, reduced risk of jams, and enhanced control over particle size.

Granulators

- Overview: Granulators are precision machines designed to produce uniform granules from LDPE film scrap. They utilize rotating knives and a screen to achieve controlled particle sizes.

- Advantages: Precision in particle size control, reduced dust generation, and adaptability for specific output specifications.

The diverse array of LDPE film scrap shredding machines provides tailored solutions for the unique characteristics of this plastic material. Whether utilizing single-shaft, dual-shaft, quad-shaft shredders, or granulators, industries can choose the most suitable equipment based on factors such as throughput capacity, particle size requirements, and operational preferences. By leveraging these advanced shredding technologies, the plastic recycling industry can effectively address the challenges posed by LDPE film scrap, contributing to a more sustainable and circular approach in plastic waste management.