Steel swarf/chips, common byproducts in equipment manufacturing enterprises, pose a significant pollution challenge within factories. Their large, fluffy nature, combined with a high oil content, leads to scattering, spreading, and dripping, causing environmental contamination. The ensuing oil leakage corrodes cement floors, reducing their load-bearing capacity. Factories must prioritize proper steel swarf/chips management to enhance environmental conditions and achieve civilized production.

Recycling Challenges

While these materials are often recycled in electric arc furnace steelmaking, the process has drawbacks. The low recycling rate (approximately 84%) and the generation of large amounts of fumes with high energy consumption are key issues. Medium-frequency furnaces, an alternative, face challenges like high suction requirements, impurity content, and the production of materials with unstable quality, making recycling a complex task.

The Role of Steel Swarf/Chips Shredder

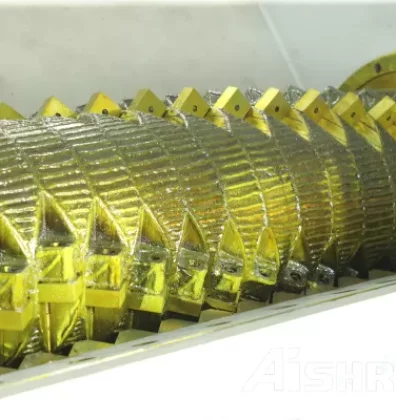

Addressing these challenges, the steel swarf/chips shredder proves to be a robust solution. Driven by a planetary gear reducer and featuring NiCrMo alloy steel cutters, it exhibits wear resistance and strength. The differential speed operation enables tearing, squeezing, and biting, controlled by a PLC for automatic overload protection.

Advantages of steel swarf/chips shredder:

- In the past to deal with the use of steel swarf/chips crusher has been gradually eliminated by the shredder,crushers tend to entangle the shaft when crushing steel swarf/chips, and excessive entanglement of the shaft by steel swarf/chips can easily cause machine crashes, jamming, and other phenomena, making it very difficult to handle and affecting production.

- Steel swarf/chips materials are relatively thin, and after prolonged operation of the crusher, the temperature inside the crushing chamber is too high. Heat can easily cause the iron filings to burn red and oxidize, resulting in the loss of iron powder during crushing and a decrease in output.

- The low speed and large output of the steel swarf/chips shredder effectively solve the above problems, and after shredding, it can be directly compressed into cakes and blocks, with small storage and transportation space.