As the service life of municipal landfills extends, large volumes of aged waste have accumulated in legacy landfill sites. This type of waste, having undergone years of natural degradation and compaction, presents a high degree of complexity in composition and is difficult to process. Despite these challenges, aged landfill waste still retains certain resource value. Given the diverse composition, sorting difficulty, and mounting environmental pressures, the use of professional, high-efficiency sorting equipment has become a critical pathway to achieve the goals of volume reduction, harmless treatment, and resource recovery. In the aged waste treatment process, the trommel screen and wind sifter act as core sorting equipment. Working in tandem, they enable the effective separation and recovery of valuable components from mixed waste streams. Trommel Screen: Efficient Screening for Removal of Soil and Humic Matter Working Principle:Driven by a motor, the rotating cylindrical drum causes waste materials to

The working principle of the wind sifter separator is mainly based on the difference in suspension speed between materials and impurities. It generates strong airflow, effectively sorting out disorderly materials while removing light impurities and dust, as well as removing some heavier impurities such as stones and soil blocks. The wind sifter separator is composed of a supply air system, a return air system, a conveying system, etc. The supply air system and return air system interact to form a regular air flow inside the box, driving lighter materials to be transported forward to the feeding hopper of the conveying system. There are two core elements to achieve its functionality in design:1,High speed airflow blows out light matter;2,Settle and collect light substances through various means.Based on the analysis of the above two points, the influencing factors include wind speed, air volume, particle size, thickness, and light material filtration.

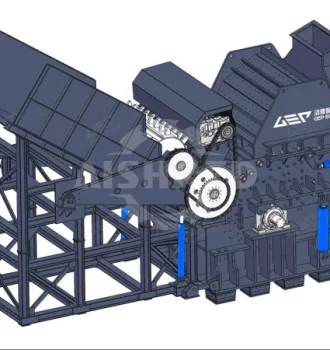

Wind Sifter Separator

2023-09-04Wind Sifter Separators are devices based on the principle of gravity separation. They separate heavy and light components in materials by utilizing airflow, allowing for precise material classification. This equipment has various variations to meet different application needs in various fields. In waste management, recycling, construction, and other industries, Wind Sifter Separators play a crucial role in improving material processing efficiency and quality.The key to the performance of Wind Sifter Separators lies in precise design and meticulous manufacturing. Any defects may lead to the risk of gas leakage or increased energy consumption, compromising the equipment's sorting efficiency.GEP ECOTECH's air separation equipment is specifically designed for waste processing and recycling, utilizing the principles of aerodynamics for exceptional efficiency. It can flexibly adjust air volume and airflow angles based on material characteristics. With a simple structure for easy maintenance, it meets the