Facts: Municipal solid waste contains a large amount of high calorific value components, which will not be effectively utilized if the waste is directly incinerated or filled up. Through the existing thermal power plants, thermal power plants, cement plants for coupling power generation, co-disposal, combined with RDF fuel briquetting production technology, without landfill, without large investment in the construction of waste incineration power plant, urban household waste, industrial solid waste can be "harmless, reduction, resource, energy" comprehensive use of treatment applications.

As MSW is incinerated directly as a solid fuel without treatment, the following main problems often exist.

- the organic matter in the waste is highly perishable, making transportation and storage more difficult.

- the waste is characterized by large fluctuations in composition and calorific value, high moisture and ash content, which can easily cause unstable combustion

- waste often contains plastic, salt and other chlorine-containing compounds, high temperature heat will produce corrosive hydrogen chloride gas, hydrogen chloride emissions can form acid rain, and can corrode metal equipment in the furnace; due to the presence of chlorine-containing compounds, may also produce highly toxic harmful substances - dioxins, forming a more serious harm to human health.

- the ash discharged after waste incineration usually contains harmful metals, such as mercury, lead, etc., which can also cause secondary pollution of the environment if not handled properly.

We have learned through the above-mentioned cases that MSW needs to be pretreated before it can be applied. The emergence of a kind of waste derivative fuel that effectively pre-treats and forms and processes municipal domestic waste before entering the furnace, and then is incinerated and utilized as solid fuel, provides a new idea to solve the above problems, and has been applied to materials such as municipal domestic waste, general industrial solid waste, paper waste slag, water washing plant waste slag, steel mill waste, textile waste, leather waste, rag waste, used garments, etc.

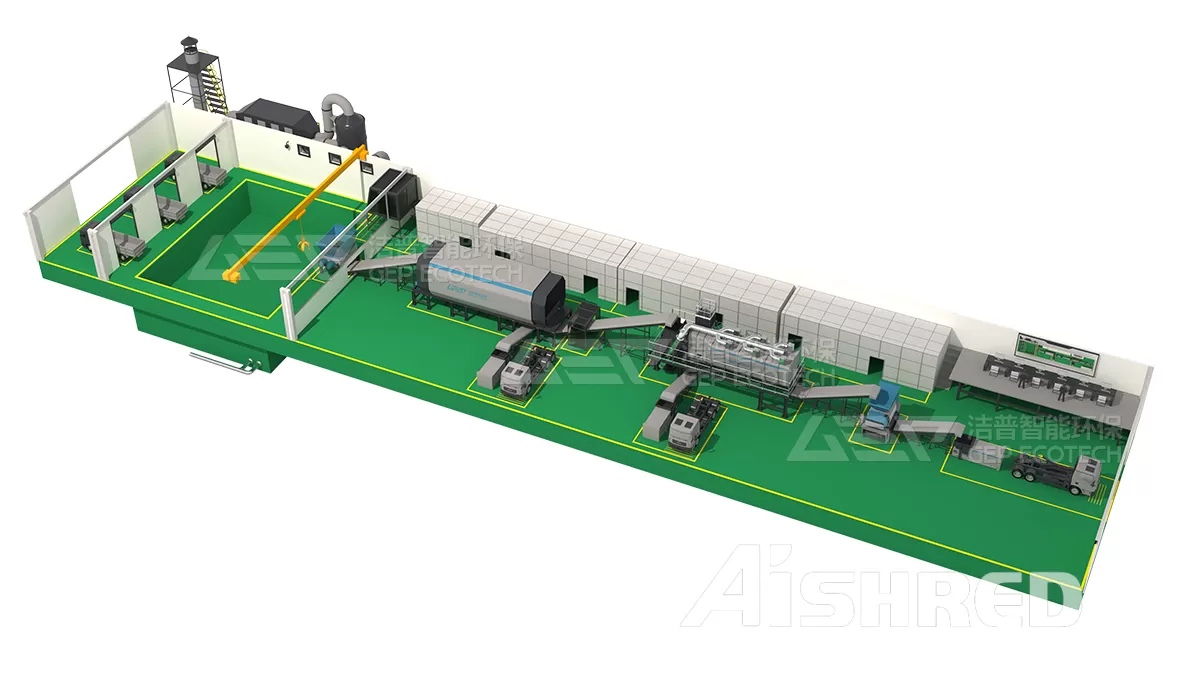

Municipal waste is crushed by primary shredder and fine shredder, and then entered into RDF forming machine and extruded into RDF high-density particles, which are used as fuel for power plant to burn and generate electricity to realize resource reuse. After RDF production line, the waste-derived fuel RDF has high calorific value, stable combustion conditions, RDF-5 volatile content of more than 75%, moisture content of less than 20% significant advantages, can be a large number of large circulating fluidized bed boilers for blending coupled power generation, a large number of alternatives to the use of coal-fired fuel, for enterprises to save a lot of coal-fired fuel costs, but also to ensure the safe, stable and sustainable operation of electricity production, and emissions fully meet the standard requirements. And emissions fully meet the standard requirements.

RDF fuel briquetting machine features

1) Adopting electromechanical-hydraulic integration technology, with mature structure and stable operation.

2) The mold is single and independent, easy to replace, convenient and quick.

3) With automatic lubrication, electro-hydraulic lubrication device, convenient for maintenance.

4) With automatic turning function, it can reverse itself when it is overloaded and bogged down.

RDF fuel briquetting machine working principle and process flow.

The briquetting machine is composed of machine base, shroud, inlet, press wheel, flat die, outlet and other parts.

The working principle is: the material to be pressed should be crushed first, its length 30-60mm is appropriate, the moisture content is within 15%-25%, the material is fed into the briquetting machine inlet by the feeding conveyor, the material is evenly dispersed into the working area between the briquetting wheel and the flat die, through the spindle rotation, drive the briquetting wheel rotation, the material is forced to extrude from the flat die into a block, and fall from the outlet.

RDF fuel briquetting technology brings life to the energyization of waste and becomes a new growth point in the field of waste utilization. It is widely used in coal-fired power plants, thermal power plants, waste incineration power plants, thermal power plants, cement plants and other enterprises, effectively accelerating the transformation and upgrading of power, gradually realizing green and low-carbon power production, and contributing to the global energy transformation.