Basic selection principles for single-shaft shredders

Before assessing the suitability of any type of shredder, the customer's specific application requirements must be clearly defined.This includes:An analysis of the type and properties of the material to be processed.

The type of feed required. What is the required particle size after crushing. What is the budget for the equipment.

More detailed issues to consider are: Will the material be fed in bales, rolls, sheets or bulk for shredding? Does the material stream contain contaminants? Is there a need for capacity reduction or a specific particle size?

As a rule, the higher the capacity of the plant and the smaller the required particle size, the more expensive the solution. For example, if the shredder is to produce 50 mm granules, then a system with a screen may be required to recover the material. Although screens can be used to obtain uniformly sized granules, they can cause some side effects, in particular they can significantly reduce throughput, some materials can clog the screen and when handling fragile chips, they can damage the screen or the whole shredder.

Advantages of the single-shaft shredder

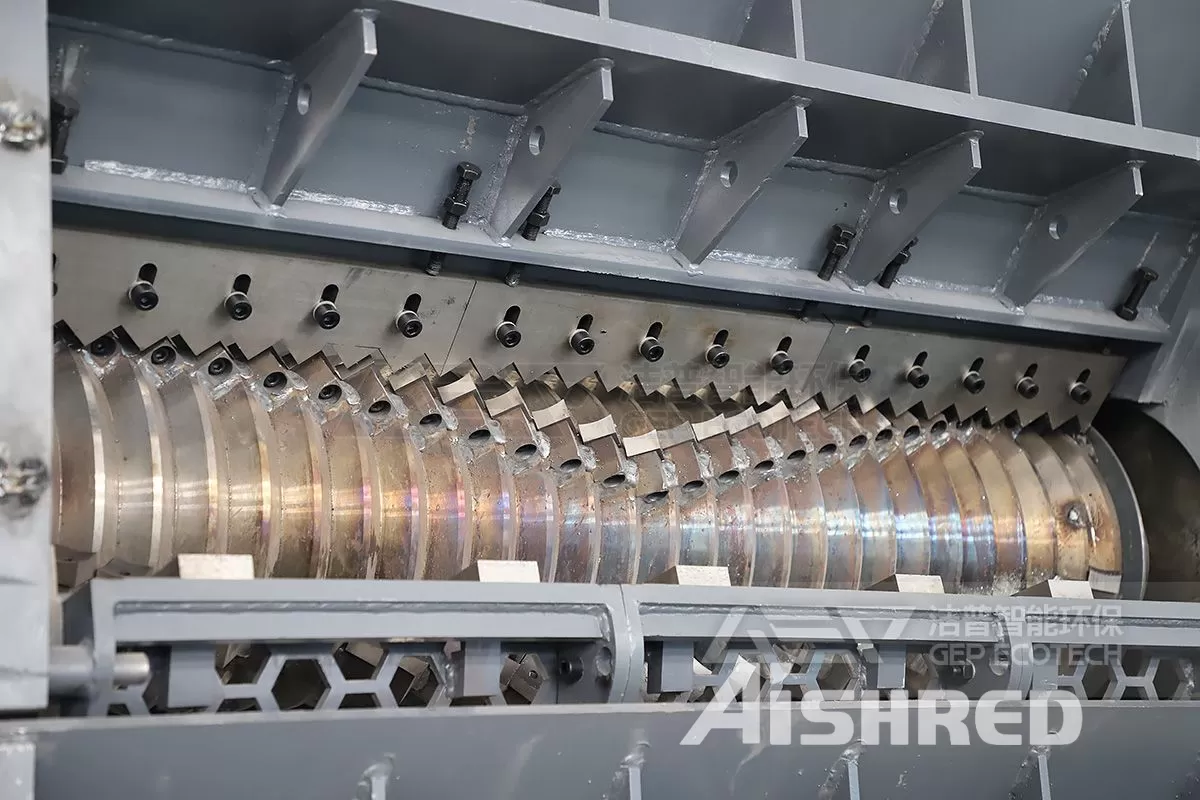

Single shaft (or single rotor) shredders are a good choice if tight particle size control is required. This technology can be advantageous for certain applications. Size control is achieved by using a sorting screen. This technology typically operates at a rotor speed of 80-110 per minute, with some types of single rotor shredders capable of operating at higher speeds.

Single-shaft shredders (single shaft shredders) are ideal for processing 'clean' materials such as plastics, foam, paper and rubber. Most designs use a horizontal plunger to feed the rotor. The size of the rotor varies and is usually between 300 and 500 mm in diameter. If a sieving grid is used, the oversized material is recirculated and processed again by the rotor until the required particle size is reached. Smaller tools can usually be turned two to four times and replaced when worn or damaged. Sieve mesh sizes usually range from 10 mm to 25 mm.

Contact us for the single shaft shredder best suited to your application.