Grocery waste, with its mix of high-moisture content, tough fibrous materials, and varying shapes and sizes, presents significant processing challenges for composting and recycling operations. Recently, GEP ECOTECH received an inquiry from a vermicomposting organization looking to optimize their grocery waste pretreatment process. The client processes approximately 3 cubic yards of grocery waste per day, including whole pineapples, potatoes, corn, and other common supermarket discards. Their goal was clear: reduce the waste size to 1/2"–1", and load the shredder using a skid steer in half-yard batches.

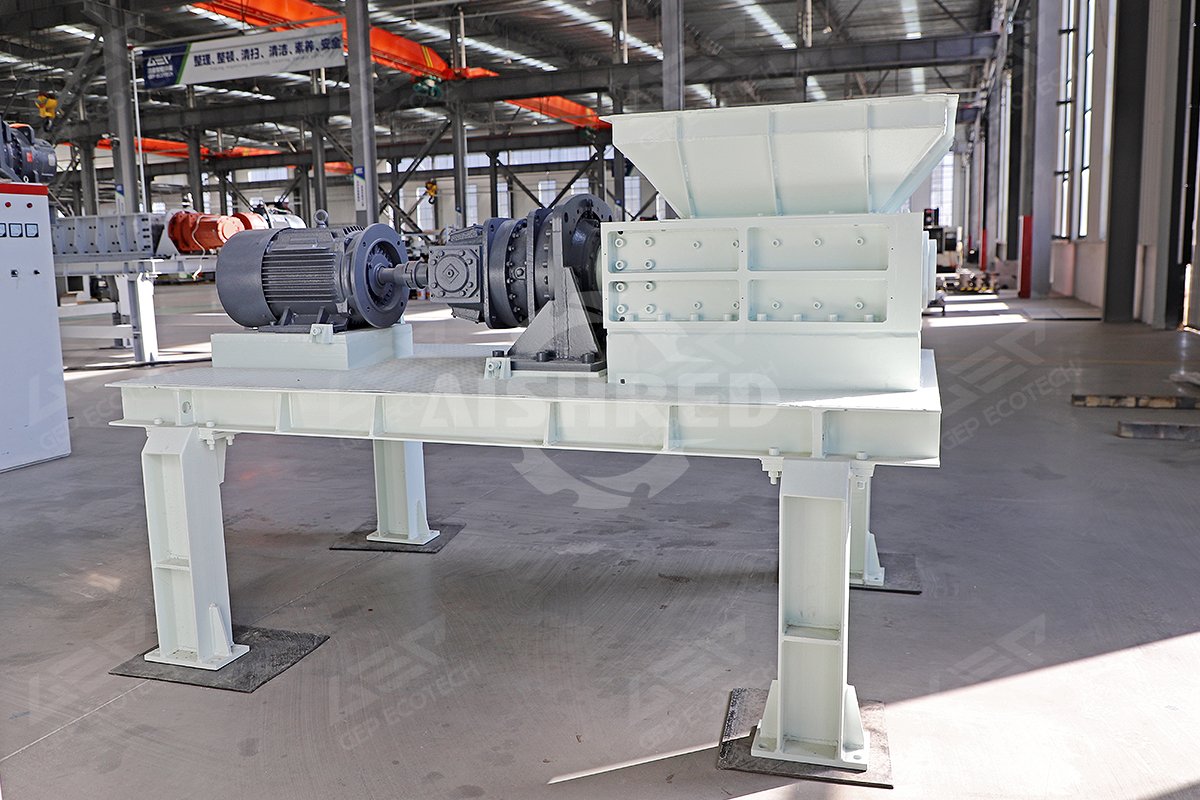

GDF5 Double-Shaft Shredder: Powerful, Reliable, and Built for Organics

To meet this demand, we recommended our GDF5 Double-Shaft Food Waste Shredder, a highly efficient primary shredder specifically engineered for food and organic waste. With a motor power of 22 kW and cutter thickness of approximately 20 mm, the GDF5 is more than capable of handling the specified throughput and delivering consistent particle sizes suitable for vermicomposting.

The GDF5 offers multiple advantages that make it ideal for this application:

- Low-speed, high-torque cutting system: Ensures powerful and energy-efficient shredding with reduced noise and wear.

- Integral cutter box: Rigid one-piece construction provides long-term structural stability.

- CrNiMo high-alloy steel cutters: Durable and wear-resistant, built to handle tough organic loads.

- Anti-winding fixed cutters: Specifically designed to resist clogging from fibrous materials like corn husks and vegetable peels.

- Hexagonal main shafts (heat-treated): Strong and stable transmission for long service life.

- Multi-sealed bearings: Effectively protect against contamination from wet, corrosive organic materials.

With its robust design and cutting-edge engineering, the GDF5 shredder ensures stable operation, consistent output size, and long-term durability in food waste applications.

Complete System Integration with Auxiliary Equipment

In addition to the main shredding unit, GEP ECOTECH proposed a set of auxiliary equipment to create a fully integrated solution:

- Feeding Belt Conveyor: Enables safe, controlled delivery of material into the shredder.

- Screw Press Dehydrator: Removes excess moisture from shredded waste to enhance composting efficiency.

- Uni-Screw Shaftless Conveyor: Smoothly transfers material without clogging or buildup.

- Electrical Control Cabinet: A centralized smart control system for monitoring and managing the entire line.

This system design allows for seamless, semi-automated processing from input to output, significantly reducing manual handling and improving overall operational efficiency.

Positive Feedback and Professional Recognition

The client was impressed with our technical proposal, especially the GDF5's ability to meet their size reduction, capacity, and loading method requirements. They appreciated the attention to detail in our equipment selection and the flexibility of our system integration. The result is a highly customized solution that will support their long-term composting operations effectively.

At GEP ECOTECH, we are proud to deliver high-performance waste recycling systems tailored to the real needs of our clients. Whether you're handling grocery waste, kitchen scraps, or other organic materials, our advanced shredding technology and integrated solutions can help you increase productivity while supporting sustainability.

Let's Talk Grocery Waste Recycling

GDF series dual-shaft shredder is specially manufactured for the treatment of biological waste. It can be used for shredding garden and kitchen waste, destroying expired food or for the disposal of slaughter waste. GDF shredder is famous for its solid structure, super high performance and long service time. It is widely used in restaurants, hotels, supermarkets, slaughterhouses, garbage management units and so on.

If you're exploring solutions for grocery waste recycling or vermicomposting, GEP ECOTECH is here to help. Our team of experts is ready to develop a custom system that meets your needs.

Contact us today to discuss your grocery waste processing challenges!