In the innovative model combining the food waste recycling with the breeding of black soldier flies, a core challenge is how to transform the complex, high oil and high water raw waste into safe, stable, and high-quality feed suitable for black soldier flies to feed on. The key to achieving this transformation lies in a set of specialized and targeted pre-processing and disposal equipment. This article will systematically analyze and recommend the core process flow and equipment configuration based on the specific needs of black soldier fly farming.

Three Major Challenges in Converting Food Waste into Black Soldier Fly Feed

Food waste is a nutrient rich raw material, and converting it into black soldier fly breeding feed faces the following three challenges:

- Complex composition: Rich in organic matter, but mixed with a large amount of inorganic impurities such as plastic, metal, porcelain, etc., which can easily damage equipment and affect the growth of larvae.

- High moisture content: Generally exceeding 80%, direct feeding can lead to anaerobic fermentation in the aquaculture environment, the production of harmful substances, and low survival rate of larvae.

- High oil content: Excessive oil (especially animal fat) can wrap around larvae, block their valves, cause suffocation, and lead to digestive problems.

Four Core Criteria for High-Quality Feed

To ensure the high conversion rate and stability of black soldier fly farming, the pre treated materials must meet the following core requirements:

- Pure and free from impurities: Thoroughly remove all physical impurities such as plastic, metal, shells, etc.

- Uniform physical form: The material should be in the form of a slurry or paste, which is convenient for larvae to feed and automate feeding.

- Moderate dryness and wetness: Black soldier fly larvae prefer a certain solid form, and materials with a moisture content of about 60% are their ideal growth environment. Excessive moisture can cause larvae to suffocate and easily lead to mold growth..

- Low fat safety: Excessive oil content (especially animal fats) in food waste can be toxic to the digestive system of black soldier larvae, affecting their growth and even leading to death. Therefore, before feeding, the vast majority of the oil must be separated through a process.

Recommended Solution: Three-Stage Pretreatment Process

To achieve the above goals, we recommend using the following market validated three-stage pretreatment process system, which focuses on graded impurity removal, homogeneous pulping, and precise oil and dehydration.

Fine Sorting and Impurity Removal System

Conveying equipment: Belt conveyor, ensuring uniform feeding of materials.

Bag breaking and coarse screening equipment: The bag breaking machine tears the packaging, and the large material sorting machine (ballistic screen) effectively separates two-dimensional impurities such as lightweight plastics and paper.

Fine sorting equipment: Magnetic separator strongly adsorbs ferrous metals; The wind separator uses wind pressure to separate light impurities; In a hydraulic cyclone, the difference in specific gravity can be used to further separate heavy substances such as sand, gravel, and glass slag.

Efficient Grinding and Pulping System

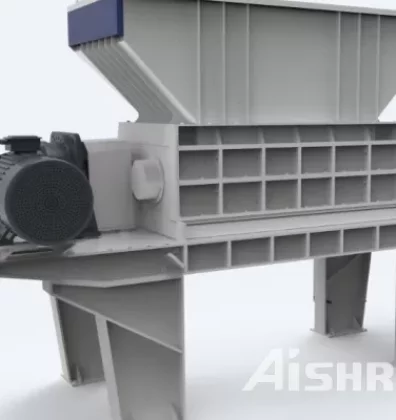

High strength shredding and pulping integrated machine: The food waste shredder has the characteristics of anti entanglement and wear resistance. Through high-speed shearing and impact, it instantly shreds fruits, vegetables, fibers, and even small bone residues into a homogeneous slurry with good fluidity, achieving "volume reduction" and "homogenization" of materials.

Core Oil and Dehydration System

Spiral dewatering machine: receives the slurry after pulping, and achieves efficient solid-liquid separation through the strong squeezing force of the spiral shaft in the sieve.

Output: Organic solid residue with a moisture content of 70%–80%—This is the main feed base for black soldier fly breeding, which can be easily adjusted to the optimal breeding humidity by adding auxiliary materials (such as bran).

Three phase horizontal centrifuge: With its strong centrifugal force generated by high speed, this equipment can accurately separate wastewater into three components:

Crude oil (light phase): a high-purity industrial grade raw material that can be sold to create significant economic returns.

Wastewater (heavy phase): enters the subsequent sewage treatment system (such as anaerobic biogas) to achieve standard discharge or energy recovery.

A small amount of sludge: can be refluxed or treated separately.

Investing in a professional set of food waste recycling equipment is not a simple cost expenditure for the black soldier fly breeding project, but a strategic investment to ensure project success and enhance comprehensive benefits.

As a leading provider in the field of solid waste treatment, GEP ECOTECH possesses profound industry expertise and advanced technological strength. We specialize in the R&D, manufacturing, and provision of complete sets of food waste recycling equipment and system solutions. Our core mission is to transform complex food waste into high-value resources through efficient and stable technological processes, creating tangible economic and environmental benefits for our clients.

By choosing GEP ECOTECH, we will wholeheartedly provide you with scientifically designed and reliable quality solutions and equipment!