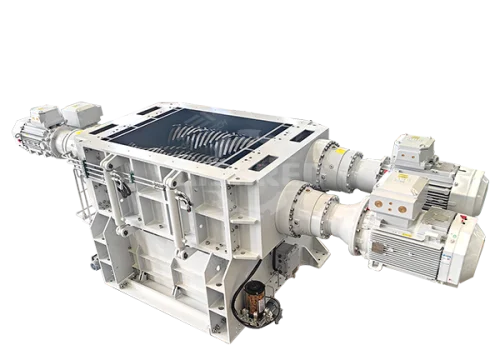

Hazardous waste barrels not only damage the ecological environment and affect human health, but also constrain sustainable development. Therefore, tit is necessary to properly treat hazardous waste barrels. As a widely acclaimed waste treatment equipment, the four shaft shredder has shown unexpected effects and advantages in handling hazardous waste barrels.

Powerful shredding ability

The four shaft shredder, with its multi shaft design and high torque rotor, is capable of shredding hazardous waste barrels, including plastic, metal, and other materials in large quantities, ensuring effective shredding.

Security handling characteristics

1) Control of hazardous waste release: The equipment structure and operation can control the release of hazardous waste, reduce environmental pollution risks, and provide a safe processing environment.

2) Avoiding secondary pollution: The shredded waste residues can be better controlled and treated, avoiding the risk of secondary pollution.

Accurate shredding control

Cutters and equipment settings can be adjusted as needed to control the discharge particle size of waste to meet different treatment needs.

Environmentally friendly and resource recycling

The shredded waste residues can be further recycled, such as through recycling or energy recovery, to promote resource utilization.

The four shaft shredder provides a reliable solution for the treatment of hazardous waste barrels with its powerful shredding ability, safety, and accurate shredding control. However, a good four shaft shredder requires a high level of experience and manufacturing process from the manufacturer. When choosing hazardous waste disposal equipment, it is essential to choose a reliable set of equipment to ensure effective and safe disposal of hazardous waste barrels.

ECOTECH has been specializing in the manufacturing of four shaft shredders for many years, and the equipment has been successfully applied in multiple projects both domestically and internationally. If you want to learn more about the equipment details, please feel free to contact GEP ECOTECH!