Roller Screen

2023-09-08Roller Screens, using a rotating disc installed on rollers, achieve the conveyance and separation of materials, suitable for screening materials with significant size variations. Roller screens excel in handling challenging materials, particularly those with high humidity, viscosity, and a high content of fine particles. Their advantages include a compact size, strong load-bearing capacity, and high throughput. The separation efficiency of roller screens can be flexibly adjusted by tuning the gap and shape of the rotating disc to meet the processing needs of different materials.When traditional screening methods fall short of requirements, roller screens prove to be particularly effective. Whether confronted with challenging mining operations or navigating the complexities of construction and waste management, roller screens emerge as a reliable and efficient solution.Choosing GEP ECOTECH's roller screen means obtaining advanced material separation technology for optimal screening results. We provide

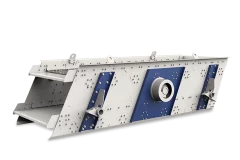

Circular Vibrating Screen

2023-09-06Circular vibrating screens are classic and widely used mechanical screening machine. Their working principle involves motors driving the eccentric blocks of vibrators at high speeds, generating centrifugal forces to stimulate the circular motion of the screen bodies, hence their name. The main advantages of circular vibrating screens include high throughput, strong adaptability, simple structures, robustness, and easy maintenance, making them the preferred screening equipment in many projects.Circular vibrating screens use multiple layers of screening mesh, which can be made of materials such as perforated plates, polyurethane, or metal mesh. In front of the circular vibrating screen, there is a material feeding buffer device to reduce the impact on the screening mesh when materials fall. The screen body is connected with bolts to enhance overall fatigue resistance.GEP ECOTECH's circular vibrating screens have been validated through years of global applications. Our engineers have conducted extensive

Multi-frequency Screen

2023-09-05Multifrequency screens employ multiple vibration sources, designed to comprehensively handle materials. Unlike traditional vibrating screens, the bodies of multi-frequency screens remain stationary while the screen mesh vibrates. This design minimizes wear and reducing energy consumption. Multifrequency screens can adjust their frequency based on material conditions, with their compact footprints, low operating costs, easy maintenance, and environmentally efficient features, multifrequency screens have become the preferred choice in many industries for fine screening.GEP ECOTECH's multifrequency screens undergo multiple technological optimizations to ensure their stable and reliable performance, along with maximum flexibility, meeting the demands of customers for efficient screening equipment.You will achieve maximum throughput with continuously excellent product quality with these high capacity screening machines.

Flip Flow Screen

2023-09-05Flip Flow Screens are improved equipment based on traditional vibrating screens, designed primarily to address the issue of screen clogging when separating sticky, wet, and other challenging materials. They utilize elastic polyurethane material as the screens, where the vibrating sources drive the movements of the screens and simultaneously apply vibrations to the elastic screens. This rapid stretching and relaxing of the screens guide the materials to 'jump,' achieving effective material separation while keeping the screen apertures clear.Flip-flow screens have unparalleled advantages compared to other screening devices, including high screening efficiency, compact structure, self-cleaning functions, low maintenance work, and adjustable vibration parameters. They are suitable for the screening of materials ranging from mining to recycling, composting to biomass, and even materials like boiler bottom ash and clay.GEP ECOTECH's Flip Flow Screens are designed for fine-screening, offering unprecedented

Trommel Screen

2023-09-04Trommel screens are one of the most widely used and efficient mechanical screening equipment. They excel in continuous separating of materials such as municipal solid waste, construction and demolition waste, wood chips, soil, compost, and other challenging substances. The trommel screen's ability to tumble materials resolves the clogging issues commonly encountered by traditional screening equipment when dealing with wet and sticky materials.However, trommel screens are not without their drawbacks. Factors such as their larger footprint, lower throughput, and the inconvenience of screen replacement pose challenges in certain applications.GEP ECOTECH's Trommel Screens are designed for prolonged use in harsh environments. Their robust and durable structures, coupled with advanced manufacturing processes, ensure reliability when handling complex materials. Our engineering team is dedicated to continuously optimizing the performance of the Trommel Screens to meet customer demands for efficient screening and