- Home

-

Product

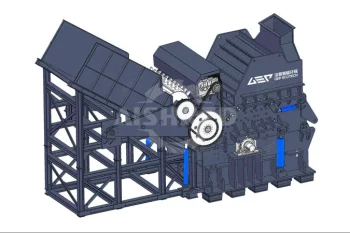

- Shredder Machine

- Double-Shaft Shredder

- Single-Shaft Shredder

- Four-Shaft Shredder

- Pre Shredder

- Hammer Mill Grinder

- More»

- Compactor & Granulator

- Hydraulic Baler

- RDF Pellet Machine

- Universal Granulator

- Rubber Grinder

- Biomass Pellet Machine

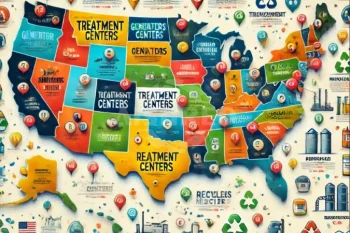

- Application

- Release

- About US

- Contact US