Printed Circuit Boards (PCBs) are high-value, highly complex electronic components rich in metals with high recovery value such as copper, gold, and palladium. They possess a complex composite material structure (laminated combination of resin, glass fiber, and metal), making recycling challenging. Efficient and stable pre-processing shredding is the foundation for ensuring the efficiency and economic viability of the entire recycling process.

Brief Description of PCB Resource Recycling Process

The standard mechanical PCB recycling process is mainly divided into three stages:

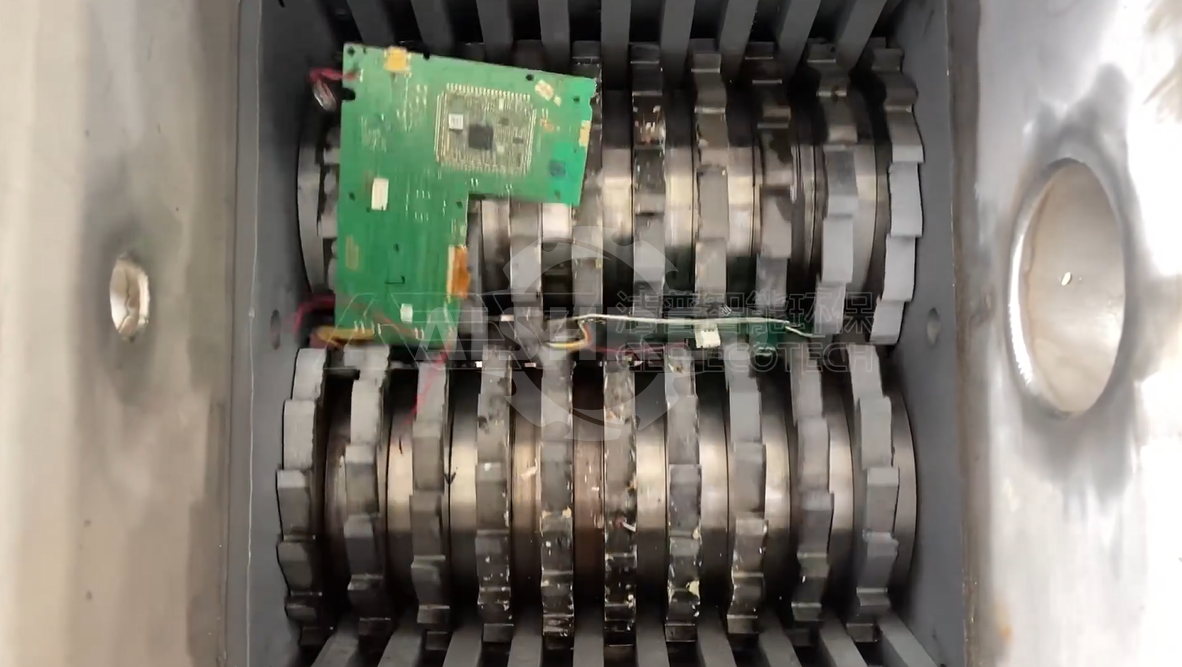

- Pre-Shredding Stage: Shredding whole PCBs into uniformly sized fragments (typically 10-50mm) to provide qualified feedstock for subsequent processes.

- Fine Shredding and Grinding Stage: Further shredding to fully liberate metals from non-metals, achieving a target particle size of 0.2-2mm.

- Separation and Enrichment Stage: Separating and enriching metallic and non-metallic materials using technologies like magnetic separation, eddy current separation, and electrostatic separation, based on differences in the physical properties of the mixture components.

Among these, pre-shredding is the primary and critical first step of the entire process. Its effectiveness directly determines the overall line capacity, energy consumption, as well as the efficiency of subsequent separation and the metal recovery rate.

Core Equipment Recommendation: GEP ECOTECH Double-Shaft Shredder

The GEP ECOTECH Double-Shaft Shredder has become the industry-preferred choice for processing various hard and complex materials, thanks to its exceptional engineering design and reliable performance. It can be certainly used as WEEE (Waste Electrical and Electronic Equipment) Shredder or E-Waste Shredder. Its robust and durable characteristics combined with precise and controllable shredding results make it perfectly suited for the critical task of PCB pre-shredding.

Core Equipment Advantages

- Efficient Shearing, Uniform Output: The equipment features a low-speed, high-torque design and high-precision processed cutters. It shreds material through powerful and stable shear force, ensuring composite materials like PCBs are broken into uniformly sized fragments, providing ideal pre-processed feedstock for subsequent stages.

- High Wear Resistance, Durable & Stable: To handle abrasive materials like PCBs containing glass fiber, the core cutters are made from imported NiCrMo high-alloy steel, offering excellent toughness and hardness. They exhibit extremely high wear resistance and impact resistance. Worn cutters can be repaired multiple times via hardfacing, ensuring long equipment life and low maintenance costs under demanding operating conditions.

- Intelligent Control System, Safe & Reliable Operation: Integrated PLC intelligent control system and overload protection mechanisms allow real-time monitoring of operating status and automatic response to abnormalities, effectively protecting the equipment's core components.

- Optimized sealing structure design: effectively controls dust and noise during high-efficiency operation.

- Flexible customization options: to be configured according to specific capacity requirements and production line layout.

- Enhanced Overall Line Efficiency: Its stable, uniform pre-shredding output can significantly improve the efficiency of subsequent fine shredding and separation equipment, reduce overall system energy consumption, and help increase final metal recovery rates and product purity, thereby optimizing the operational benefits of the entire process.

Typical Applications

Suitable for pre-shredding various materials including waste PCBs, electronic scrap, metal composite materials, and other industrial recycling materials.

With its reliable quality and excellent adaptability, the GEP ECOTECH Dual-Shaft Shredder is a solid foundation for building efficient PCB recycling production lines and various resource recovery projects.

Contact us to obtain detailed technical information and tailored solutions.