The environmental community agrees that "solid waste is a misplaced resource", so if you decide to use a shredder to dispose of them in order to make use of the "resource", beware! The wide variety of shredders on the market can be not only dazzling but also confusing. There are even a variety of equipment names: granulators, shredders, crushers, and so on. But for professional solid waste shredding equipment providers, such as GEP ECOTECH, shredder generally refer to single-shaft, twin-shaft and multi-shaft shredding equipment.

On the surface, there is a wide range of shredders readily available, and promotional videos show shredders that can always "eat up" material quickly, with amazing output and results. Unfortunately the reality is that no single shredder can handle different wastes perfectly. Providing the right shredding solution for solid waste requires a deep understanding of the performance and advantages and disadvantages of each type of shredder, and then careful selection. The basic principles of selection are the same, however, and all require a clear analysis of the customer's specific needs, including material type, feed and discharge methods, material components and percentages, required shredding size, approximate subsequent processes, cost budget, etc. Specifically the following questions need to be determined, in what form will the solid waste enter the shredder? In bales, bags, rolls, sheets or loose form? Does the material contain hazardous or flammable materials? Is the purpose of shredding to reduce the volume or to obtain a specific particle size? Usually the smaller the size needed, the more expensive the shredding cost, so it is important to be clear about the cost and profitability of the requirement. For example, if you require material to be shredded to a size of 50*50mm, word shear shredding is not enough for the shredder and the shredder must be equipped with a screen to ensure the size. But things always have two sides, the screen on the one hand to ensure the size of the material, on the other hand will reduce the output, increase the cost of shredding, and non-shredded material into the screen after the difficult to exclude may lead to equipment damage.

Twin-shaft shear shredder - High Efficiency, Low Cost

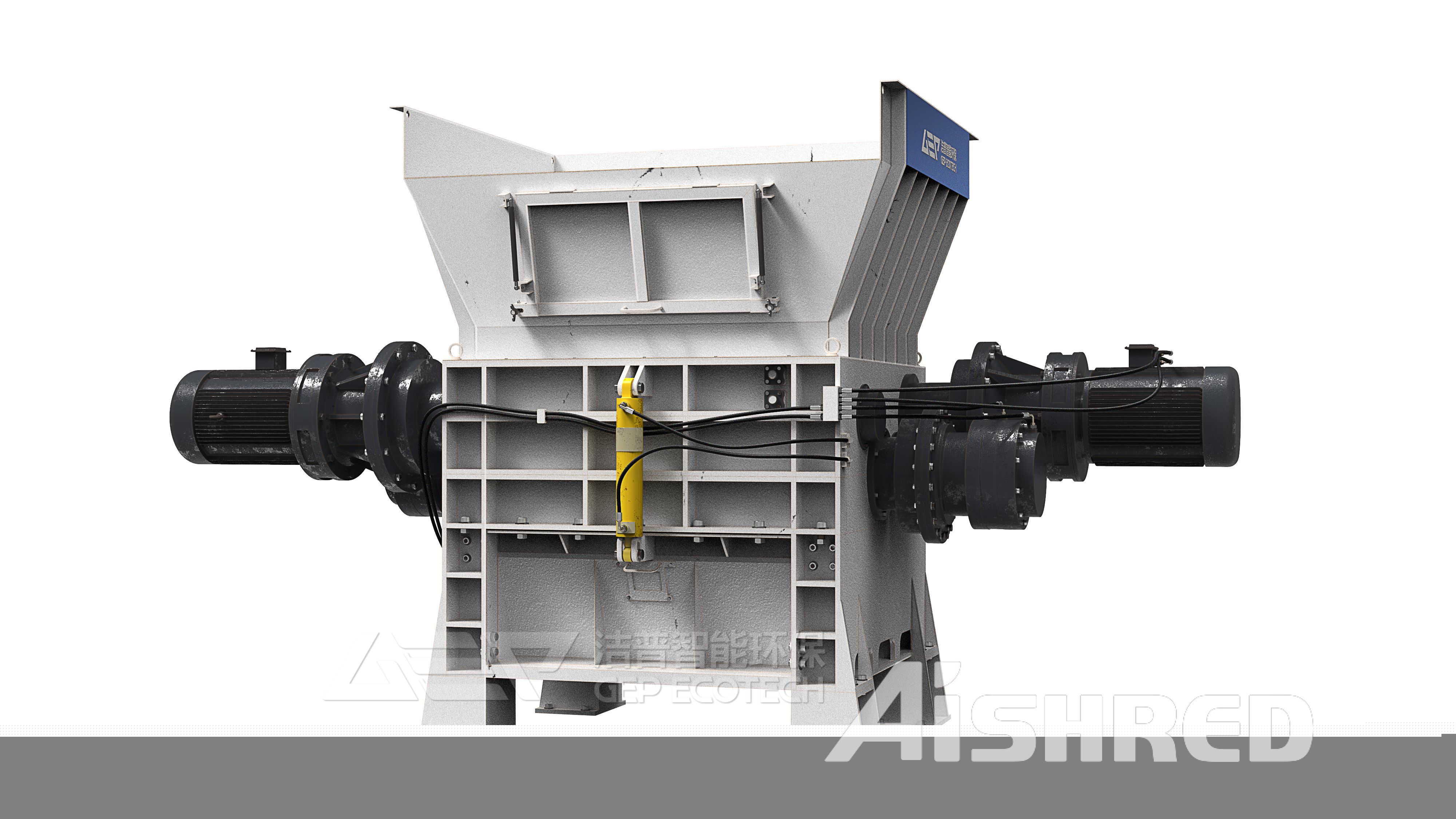

The low-speed, high-torque twin-shaft shear shredder can be called a solid waste "harvester" and is used to shred a wide range of solid waste, including biomass, household waste, tires, metals, industrial waste, electronic waste, plastics and paper. Because this twin shaft shredder has many advantages, especially it can handle solid waste containing large pieces of metal or other unbreakable items, thanks to its configuration of heavy alloy blades that not only have both strength and hardness, but also have automatic reversal protection when encountering unbreakable materials. In addition, the alloy blades can be repaired by direct overlay welding after wear, which extends the overall service life of the blades. In summary, the appropriate size of twin shaft shredder can be used to complete the shredding of complex composition solid waste in an efficient and cost effective manner. For example, GEP ECOTECH can provide twin shaft shredders with power ranging from 4KW to 400Kw to meet different solid waste shredding needs. Most of the dual shaft shredders discharge material in long strips of varying degrees, the width of which depends on the width of the cutter. Small shredders for confidential document destruction or kitchen waste mostly use knives with thicknesses below 20mm, while medium and large shredders (with power greater than 45Kw) mostly use knives with thicknesses of 30-60mm. To sum up, although the twin shaft shredder has high material inclusion and high output, the discharge size and discharge uniformity are difficult to control.

Single Shaft Shredder - High Speed Shear, Controlled Discharge

Single shaft shredding technology is an excellent choice for shredders that require uniform and controlled discharge size, and is advantageous in certain material shredding applications. Single shaft shredders obtain a defined size of material through a screen with a spindle speed typically in the 80-120 rpm range, and can even operate at 350 rpm for higher purity materials (e.g. RDF). Single shaft shredders are the ideal technology choice for "pure" solid waste such as RDF, leather fabrics, wood, paper, rubber and even some aluminum metals, which must be equipped with a press to force the material "onto" the knife rolls to facilitate shearing of the material by the knife particles. Knife roller diameter is usually between 300-1000mm, knife roller fixed with a certain number of size 30-110mm square knife grain, and fixed in the frame of the fixed knife to form a cooperative shear; knife roller is wrapped by the screen, too large material will be knife roller repeatedly shear broken, until its size can pass through the screen holes. Cutter because of the existence of four angles, can be rotated two to four times, until all the angles are worn out, then need to replace the cutters.

Although the single shaft shredder has the advantages of uniform discharge and controllable particle size, it also has its limitations. The hardness and brittleness of the cutters rotates at high speed with the shafts, and once it encounters large pieces of metal or unbreakable materials, damage to the cutters or even the shaft may occur. In addition, the high speed rotating cutters rolls and material friction heat, may cause some dry materials to catch fire, experienced shredder manufacturers usually selectively configure the fire fighting system according to the different solid waste.

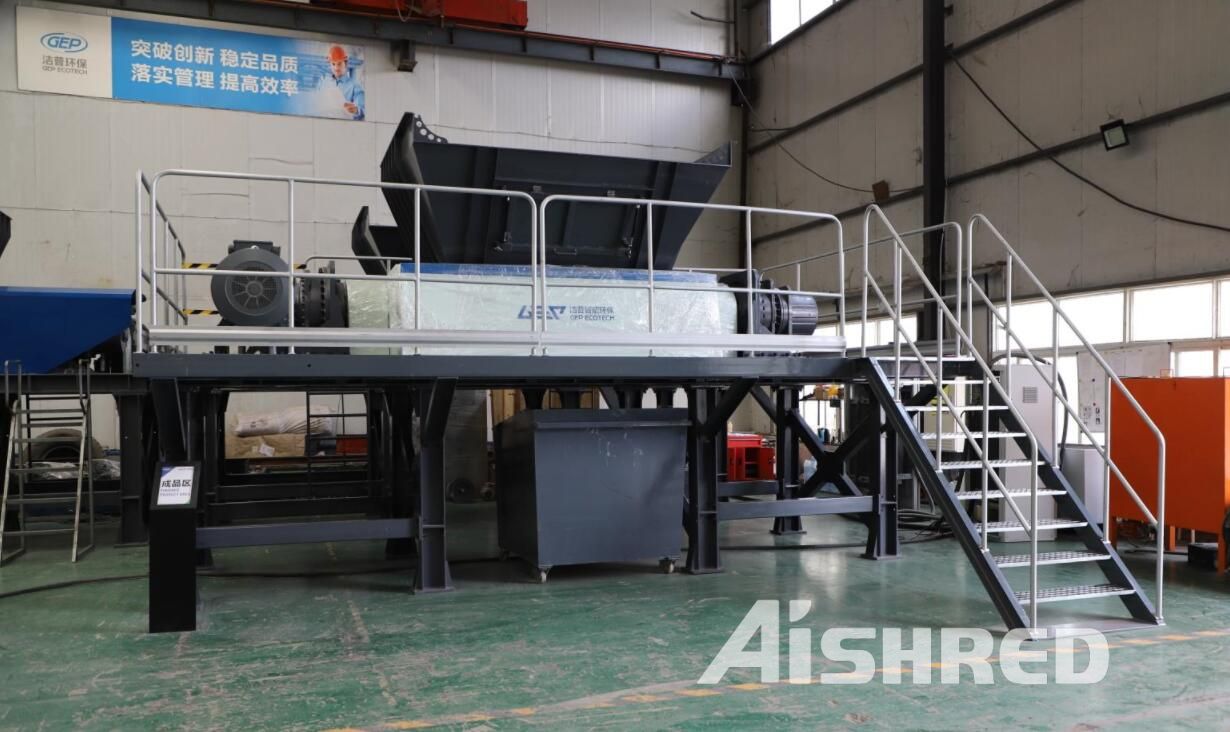

Four-shaft shredders - Look Like a Twin-shaft, Discharge Like a Single-shaft

In addition to twin-shaft and single-shaft shredders, a quad-shaft shredder exists that combines the low speed and reliability of a twin-shaft shredder with the addition of a screen at the bottom of the rotors for size control. Similar to the twin-shaft shredder, Four-shaft shredder is also through the mutual shear between the blades to achieve material shredding. The top two sets of rotors are used to grasp and eat the material, clean the spindle and assist in shearing, while the bottom two sets of rotors are used to shear the material. The large, high capacity (power shear area) four-shaft shredder from GEP ECOTECH is suitable for mixed solid waste that requires uniform discharge and may contain large pieces of metal or difficult to shred materials, such as industrial hazardous waste and electronic waste.

Summary

In summary, no one shredding technology or shredding plant can meet all solid waste shredding requirements, no matter how reliable the design or how advanced the performance, because each type of shredder has its own strengths and weaknesses, and a certain type of shredder that performs well in some applications may not be able to perform well in others. When selecting a shredder, it is important to work with a shredder supplier who has experience in the application, because not only can they provide a reliable shredder, but they can also draw on the supplier's long experience to develop a suitable shredding solution for you. Of course, it is still effective to provide the solid waste to be shredded to GEP ECOTECH for the actual material trial. As a responsible and professional solid waste equipment supplier, it is not too much to emphasize the basic principles of equipment selection.