While leather waste accounts for a smaller proportion compared to cardboard (which carries a 75% scoring weight), its recycling value is comparable to metals and plastics. However, traditional leather recycling faces three major pain points:

- Low Sorting Efficiency: Mixed leather waste (containing metal fasteners, wires, etc.) is difficult to sort manually at scale.

- High Transportation Costs: Bulk leather waste occupies significant space, making direct transportation uneconomical.

- Resource Waste: Unshredded leather cannot be efficiently separated into reusable components (e.g., fibers, metals).

Why Adopt a "Shredding and Recycling" Method?

By integrating GEP ECOTECH's intelligent Shredding and Recycling technology, the economic benefits of leather recycling can be significantly improved.

Significant Advantages

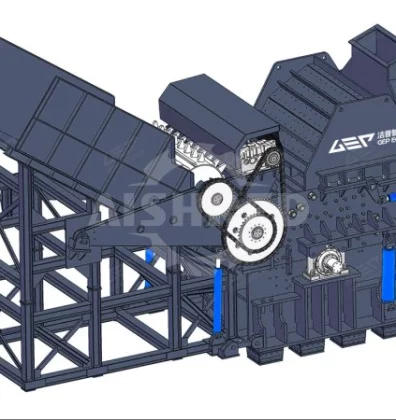

The GEP ECOTECH's Leather Shredder can quickly break down waste leather into scraps around 50-300mm, with a processing capacity of 5–10 tons/hour (based on GEP ECOTECH field tests). It adopts a heavy-duty double-shaft shredder design, equipped with wear-resistant cutters and a high-torque, low-speed motor system. This enables it to effectively shred various types of leather—including genuine leather, synthetic leather (PU, PVC), laminated leather, and composite fabrics—without wrapping, clogging, or overloading.

Wide Material Adaptability

From thick cowhide offcuts to soft, flexible leather trimmings, the machine can handle diverse leather waste forms, including production leftovers, rejected items, leather bags, gloves, and even laminated textile-leather composites.

Lower Overall Costs

Shredded leather reduces volume by 60%, significantly cutting transportation costs (aligned with the financial optimization strategy of the government).

Maximized Resource Utilization

Shredded leather particles can be further sorted via trommel screens (for fiber separation) and magnetic separators (for metal recovery), achieving up to 98% metal recovery.

Three Key Applications for Shredded Leather

We can see the above reasons for shredding and recycling leather waste, and also there are some key applications for the shredded leather. Such as:

Recycled Fiber Materials

Shredded leather fibers can be repurposed into acoustic insulation or filler materials, with a profit margin of approximately ¥2,000/ton.

Metal Recovery

Metals like copper and iron extracted via GEP ECOTECH magnetic separators can be directly fed into the "copper wire (¥25/kg)" recycling channels.

RDF Fuel

Non-recyclable leather fragments can be processed into refuse-derived fuel (RDF), with a calorific value of 4,000 kcal/kg, aligning with eco-friendly energy trends, wich is ideal for leather factories, recycling stations, RDF preparation lines, and waste-to-energy applications.

Operational Recommendations

During the operation, we have some recommendations for you.

Pre-treatment Process Optimization

Install shredding lines in waste storage areas to enable "shred-on-arrival" processing.

Compliance Assurance

Equip systems with certifications (e.g., CE, ISO 14001) to meet different customers' "recyclable resource licensing" requirements.

The shift toward shredding and intelligent leather recycling is inevitable. GEP ECOTECH's integrated "shredding and recycling" solution not only fulfills the technical demands of customers' requirements, but also unlocks additional revenue through high-value resource recovery.

Choose GEP ECOTECH's Leather Shredding and Recycling Solution to turn waste into value with efficiency, durability, and minimal maintenance. Whether you're handling industrial leather scraps or mixed textile-leather waste, we deliver tailored systems to meet your production and environmental goals.