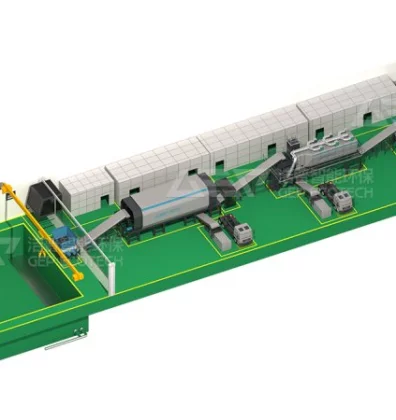

A waste transfer station serves as a centralized facility where municipal solid waste (MSW) is collected, sorted, and consolidated before being transported to its final destination, such as a landfill or waste-to-energy plant. By enabling the use of larger transport vehicles for long-distance hauling,waste transfer stations help reduce the number of trips required by smaller collection trucks, thereby improving overall efficiency.

To meet the growing demand for efficient and sustainable MSW handling, GEP ECOTECH has developed a comprehensive, modular solution tailored for modern transfer stations. This system features a new-generation MSW shredder, screening system, conveying system, sorting units, and compression equipment—all working together to streamline waste reduction, material recovery, and energy generation.

Key Equipment Overview

The system includes a specialized MSW shredder, trommel screening system, conveying equipment, magnetic separators, sorting platforms, and compression units. These components work together to streamline the treatment of mixed household waste, enabling both volume reduction and material separation at the transfer site. The core equipment of the system are double shaft shredder ,trommel screen and Horizontal hydraulic baler.

Municipal Solid Waste Shredder (Double-Shaft Shredder)

This is the core equipment of the system, designed specifically for the complex composition of household waste. The double-shaft shredder (MSW Shredder) uses low-speed, high-torque shearing to tear through materials such as packaging waste, kitchen scraps, textiles, plastics, and even lightweight metals.

Equipped with a smart control system, it can automatically reverse to prevent overloading or jamming, ensuring reliable long-term operation. The cutting chamber is optimized for easy maintenance, and the wear-resistant blades can be replaced or adjusted according to material types. With a large throughput and stable output size, this shredder prepares waste for effective downstream separation and volume reduction.

Trommel Screen (Rotary Drum Screen)

After shredding, the waste passes through the trommel screen—a key equipment of MSW sorting plants—which separates materials based on particle size. Finer organic fractions, such as food waste and small debris, fall through the mesh and are directed for composting or biological treatment. Larger fractions including plastic films, wood, and textiles, are sent for further sorting or energy recovery.

The trommel's modular design allows for easy mesh replacement and customization of screen sizes. It operates with high efficiency and low energy consumption, reducing manual handling while improving separation accuracy.

Horizontal Hydraulic Baler

As the final step in the processing line, the horizontal hydraulic baler compacts sorted and residual waste into dense, uniform bales for easier handling, storage, and transportation. This equipment plays a vital role in reducing the overall logistics cost and improving site cleanliness and space utilization.

The baler features a high-pressure hydraulic system capable of compressing a wide range of materials, including plastics, paper, textiles, and light combustible waste. With programmable automatic cycles and safety interlocks, the machine ensures stable, continuous operation with minimal manual intervention. The bale size and compression force can be adjusted to meet specific transportation or incineration requirements, making it a flexible solution for transfer stations aiming to streamline downstream processes.

Supporting Systems

In addition to the core machines, several auxiliary components work in tandem to optimize the entire process flow:

- Magnetic Separator: Removes ferrous metals from the waste stream, protecting downstream equipment and allowing for metal recycling.

- Manual Sorting Platform: Allows for the recovery of valuable materials such as plastics, cardboard, and textiles by trained personnel.

- Belt Conveyor System: Connects various stages of the process, ensuring continuous and smooth material handling.

- Compactor: Final volume reduction is achieved using a compression unit, improving transport efficiency and reducing disposal costs.

If you're exploring sustainable options for MSW treatment at your waste transfer station, we welcome your inquiry and look forward to offering customized solutions that deliver long-term value.