There is a lot of domestic waste produced in cities every day, which is increasing. Therefore, it is an urgent task to seek a way of recycling treatment of municipal solid waste. Converting municipal solid waste into waste derived fuel, namely RDF (Refuse Derived Fuel), is a mature waste treatment method in developed countries. RDF fuel has been widely used in the United States, Europe, Japan and South Korea to generate electricity or heat.

How Does Municipal Solid Waste Become RDF?

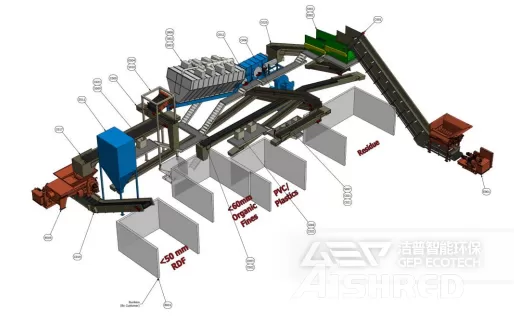

The production process of RDF is to first use sorting equipment to classify urban domestic waste, separate the recyclable parts according to different material properties, and then separate the waste plastics, waste paper scraps, wood chips, PVC and other combustible wastes from the waste through screening steps such as magnetic separation, air separation, non-ferrous metal screening and other steps, and then crush, dry and grind them into granular fuel. RDF is extruded and solidified into granules at high temperature. The RDF fuel is chalk shaped, with a diameter of 15-20mm and a length of 30-50mm. The moisture content is controlled below 12%. Its calorific value is close to that of coal. It can be widely used in waste power plants, cement plants, various industrial boilers, etc.

GEP ECOTECH Municipal Solid Waste (MSW) to Refuse-Derived Fuel

What Equipment Are Used to Prepare RDF from Municipal Solid Waste?

- Metal separator

- Air separator

- Non ferrous metal separator

- Screening equipment (roller screen, flip-flow screen, etc.)

- Primary Shredder

- Secondary Shredder

- RDF Pelleting machine

The calorific value of RDF is 14595-20016 kJ/kg. Another kind of waste derived fuel that can produce higher calorific value is called RPF, whose full name is Refuse Paper and Plastic Fuel. It is a solid waste derivative fuel made of waste paper and plastic sorted from industrial waste and domestic waste as raw materials and crushed into shapes. Its calorific value ranges from 20900-41800 kJ/kg. If you want to know more about RDF/RPF production line, please feel free to contact GEP ECOTECH!