When it comes to crushing plasterboard and gypsum, there are several types of equipment to choose from, each with its own advantages and suitability depending on your specific needs and requirements. Here are some common equipment options for crushing plasterboard and gypsum:

Hammer Mill or Hammer Crusher

Advantages:

Cost-effective option for small-scale operations.

Simple design and operation.

Can quickly crush plasterboard and gypsum.

Considerations:

May produce a significant amount of dust.

Limited control over the final particle size.

Not suitable for large-scale production.

Jaw Crusher

Advantages:

Suitable for moderate-scale production.

Provides better control over the particle size.

Lower maintenance costs compared to some other options.

Considerations:

Higher initial investment.

May require secondary crushing for finer particles.

Consumes more energy compared to other options.

Cone Crusher

Advantages:

Suitable for large-scale production.

Offers precise control over particle size.

Efficient for creating fine gypsum powder.

Considerations:

Higher initial cost and energy consumption.

Requires skilled operation and maintenance.

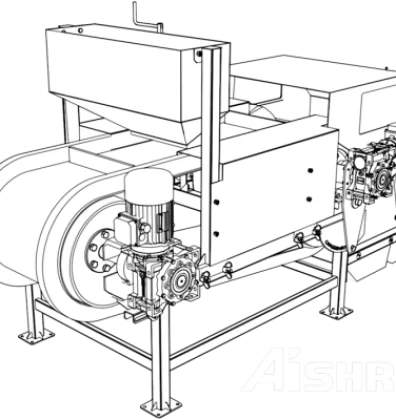

Double-Shaft Shredder

Advantages:

Versatile and suitable for various production scales.

Offers adjustable particle size control.

Durable and low maintenance.

Considerations:

Initial investment cost may be relatively high, but long-term cost-effectiveness can be good.

Requires proper maintenance and cleaning for optimal performance.

Vibrating Screen and Impact Crusher

Advantages:

Effective for separating impurities and recycling plasterboard and gypsum.

Good control over particle size.

Can be part of a larger recycling system.

Considerations:

May require additional equipment for complete processing.

Suitable for recycling facilities.

The choice of equipment should be based on your production scale, desired particle size, budget, and specific application. For small-scale operations, a hammer mill or jaw crusher may suffice, while larger-scale production may benefit from cone crushers or double-shaft shredders. Recycling facilities often use a combination of vibrating screens and impact crushers to efficiently process gypsum boards and separate impurities.

Before selecting equipment, it's essential to assess your specific requirements and conduct a cost-benefit analysis to determine the most suitable option for your gypsum board crushing needs. Additionally, ensure that your chosen equipment complies with safety and environmental regulations for C&D waste processing and recycling.