The treatment and management of hazardous waste occupies an important position in the field of environmental protection, and shear shredders, as one of the key equipment, are widely used in the field of hazardous waste shredding. This article will delve into the reasons why shear shredders are often used in hazardous waste shredding, and reveal their advantages and applicability.

Working principle of shearing shredder

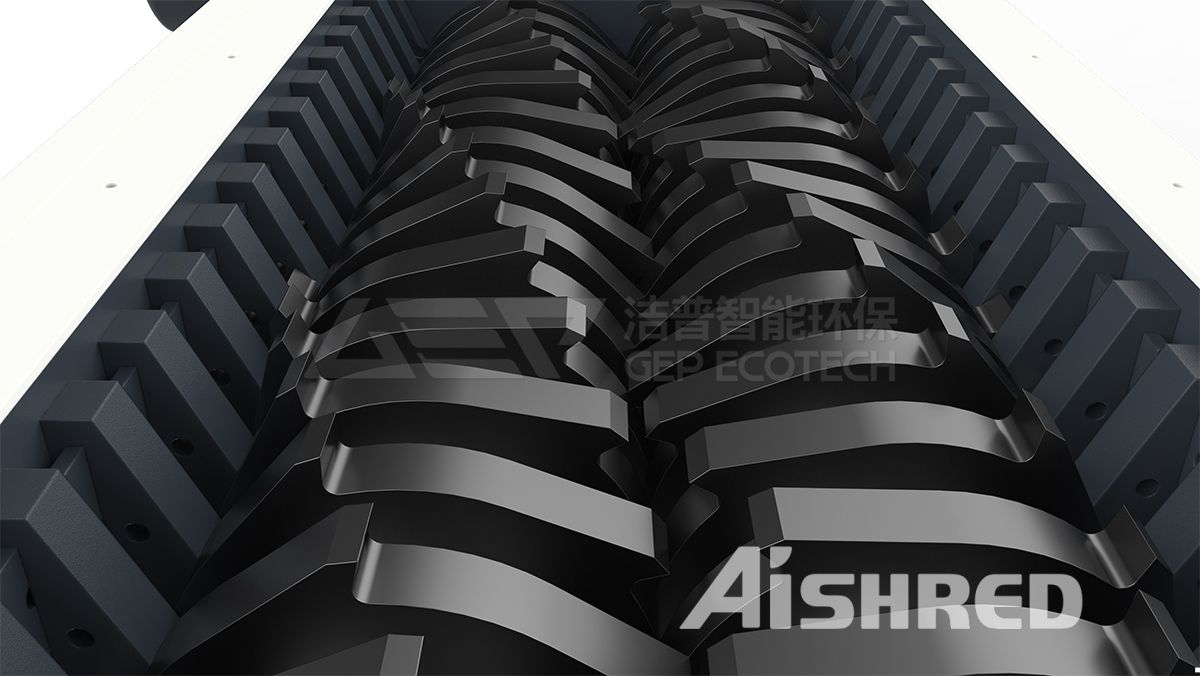

The shear shredder cuts and tears the waste into smaller particles through high-speed rotating blades. Its working principle is to place the waste between the blade and the counter knife, and decompose the waste by shearing, tearing and other forces. Shear shredders usually have multiple blades such as dual shafts, quad shafts, etc., which can effectively cut waste into pieces of different sizes.

Advantages of Shear Shredder in Hazardous Waste Shredding

- Wide adaptability: The shear shredder is suitable for processing many types of hazardous waste, such as metal waste, plastic waste, rubber waste, etc. This broad adaptability makes it ideal for a wide variety of hazardous waste disposal options.

- Effective shredding: The blades of the shearing shredder have powerful shearing capacity, which can handle larger lumpy waste and quickly cut it into smaller particles, improving the shredding efficiency.

- Strong Stability: Since the shear shredder is specially designed to handle tough waste, its structure is stable and durable, and it can maintain good performance under high-load working conditions.

- Accurate control: The number and configuration of blades can be adjusted according to waste types and processing needs, so as to achieve accurate control of the crushing process and make the output fragments more uniform in size.

- Hazard Reduction: Shear shredders help reduce the potential hazards and environmental impact of hazardous waste by breaking down waste into relatively small particles.

Application examples in hazardous waste shredding

Shear shredders are widely used in hazardous waste treatment. For example:

- In the recycling of waste electronic products, shear shredders can effectively cut electronic waste into small particles, which helps to extract valuable materials.

- When recycling waste oil barrels and paint barrels, the shearing shredder can quickly cut waste barrels into pieces, creating conditions for subsequent processing.

Shear shredders have been widely used in the field of hazardous waste shredding due to their advantages such as wide adaptability, strong crushing capacity, stability and accurate control. By breaking hazardous waste into smaller particles, the shear shredder helps to increase resource recovery, reduce environmental pollution, and reduce the potential threat of hazardous waste to human health and the environment. Therefore, the status and role of shear shredders in hazardous waste treatment cannot be ignored.