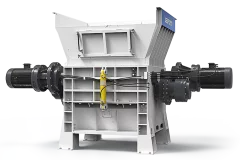

In the realm of industrial waste management, the effective processing of cast iron waste is a crucial aspect. Industrial cast iron waste shredders play a vital role in breaking down and preparing these materials for further processing or recycling. Let's delve into various types of industrial cast iron waste shredders, each designed to meet specific needs and requirements in waste management processes.Dual Shaft ShreddersCharacteristics: Dual shaft shredders have two parallel shafts with interlocking blades, enhancing the efficiency of shredding and reducing the size of cast iron waste particles.Applications: Versatile and powerful, dual shaft shredders handle various forms of cast iron waste, producing smaller and more manageable pieces.Quad Shaft Shredders:Characteristics: Quad shaft shredders, with four parallel shafts, provide even greater cutting power and versatility in processing dense and challenging materials like cast iron waste.Applications: Well-suited for heavy-duty industrial applications, quad

AIShred New Upgrade Four-Shaft Shredder

2022-04-08AIShred presented the new industrial shredder series at new factory in XinXiang Zhengzhou. This is the new family of 4-shaft shredders which is added to the already wide range of products. The new shredder is available in 4 versions to offer a modular choice suitable for multiple industries and needs. The various models are designed to process materials such as paper, cardboard, plastic, hospital waste, wood and post consumer products in aluminum and plastic, packaging and much more. The machine is aimed at all those applications where it is necessary to control the final volume of the processed material. Customization is achieved by playing on the size of the selection grid and on the thickness of the blades in order to obtain the required material size. At the management level, the machine is equipped with a management and control PLC, with components that, allow communication and control of the machine in line with the most advanced needs of the Internet of Things. The revolution of this shredder series

Four-Shaft Shredder

2022-03-03Four-shaft shredders are designed to process challenging materials into uniform sizes in a single pass. Compared to dual-shaft shredders, they feature two additional auxiliary shafts for extra shearing force, and the classifier screen that allows to define the output size.Maintaining four-shaft shredders poses a significant challenge, particularly when it involves replacing or repairing the bottom blades. This intricate process demands highly skilled technicians with specialized tools and can extend over many hours.GEP ECOTECH four-shaft shredders are suitable for most size reduction and heavy-duty applications. We recommend using them for handling complex materials and when there are strict output size requirements for single-stage shredding.GEP ECOTECH four-shaft shredders are renowned for their robust construction and powerful drive shafts. We utilize top-tier materials to enhance blade longevity and equip them with robust electrical or hydraulic drives, along with an intelligent control system. This