Amorphous strips, commonly used in the production of high-efficiency transformers, magnetic cores, and various electronic components, require specialized shredding equipment to handle their unique material properties. Due to the thin, ribbon-like structure and the toughness of amorphous alloys, selecting the right shredder is crucial for efficient processing. GEP ECOTECH, a leader in the shredding and recycling industry, recommends the dual-shaft shredder as an optimal solution for shredding amorphous strips.Why GEP ECOTECH Recommends Dual-Shaft Shredders for Amorphous StripsGEP ECOTECH's dual-shaft shredder is highly effective for shredding amorphous strips due to its combination of precision, power, and adaptability. Here are some reasons why the dual-shaft design is ideal for this application:High Torque, Low Speed Operation: The dual shafts operate at low speeds with high torque, which allows for the efficient shredding of tough materials like amorphous strips without producing excessive heat or causing

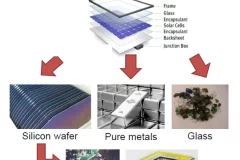

The lifespan of solar photovoltaic panels is about 25 years, and more than 95% of the material can be recycled from scrapped and damaged solar PV panels using the latest technology. Aluminum frames can be recycled and sent to refineries, glass can be recycled into glass products, combustibles such as plastics can be recycled for energy, silicon can be reused in the precious metals industry, and heavy metals can be recycled. Due to the rapid development of the photovoltaic industry, a large amount of photovoltaic waste is about to be generated. How to efficiently recycle photovoltaic waste will soon become an important challenge for us. AIShred's low-speed dual-shaft shredder have been successfully applied in solar pv panels recycling plant in a photovoltaic power plant in western China. "This is an experimental photovoltaic waste recycling project. The overall process is to disassemble the aluminum frame, thermally separate the panels, then shred and sort. We chose AIShred among European brands and many

Double-shaft Shredder for Sale in Germany

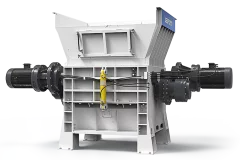

2022-04-21The double-shaft shredder for sale in Germany is a slow speed shredding equipment designed for processing various materials. The double-shaft shredder can handle most types of materials, from waste paper to plastics and hard goods. The advantage in this process of double-shaft shredders is the low speed of rotation of massive shafts, which makes it possible not to quickly grind large, hard products or chew plastic ones, grinding them into crumbs. The manufacture of parts from wear-resistant metal in combination with this principle of operation also helps to save the double-shaft shredder from damage, since there is no constant impact at high speeds. The speed of rotation of the working parts of the shredder reaches about 100 revolutions per minute. The shredder provides efficient processing with knives that look like discs with protruding teeth. The cutters are mounted directly on two rotors that rotate towards each other, are installed in a checkerboard pattern and leave a space on each of the shafts, into

The market today presents a wide range of industrial shredders with different characteristics: low speed, high speed, primary, secondary, etc., and choosing the right shredder to meet the needs of the moment can be extremely difficult. All the machines offer basic technology, and particular settings that could lead astray in the purchasing process. In choosing the ideal machine for shredding waste, the characteristics to be taken into consideration today more than ever are therefore:versatilitythe speed of execution of the workease in maintenance operationsQuick and easy change of gridsThe versatility of a shredder that allows you to process different types of waste, in the desired size, is due to its preliminary settings. Through the adjustment of the grate it is possible to shred the waste in the desired size, but it is also through the time spent in its adjustment (and therefore of the machine downtime) that the real revenue coming from the machine is calculated. The ability to change the grid in a very

Slow Speed Industrial Shredder for Sale

2022-04-07AIShred twin shaft low speed shredders are designed to reduce the volume of various materials by grinding the feedstock to a smaller size fraction. It can process materials such as: all types of MSW, C&I Waste, any wood, tires,, plastic wastes, carpets, mattresses, sofa and other materials. By reducing the volume of the source material by several times, this equipment can be used in the following cases:At landfills for shredding bulky waste - extends the life of the landfill by 20–30%;At sorting stations and waste processing plants - for shredding KGM and MSW with the simultaneous function of a "bag opener";At enterprises for the processing of wood waste - for chipping wood;In conjunction with a solid waste press packer - for preliminary shredding of solid waste;At manufacturing enterprises where shredding of various materials such as production waste, drywall, batteries, etc. is required.Shredders can be driven either by electric motor or by hydraulic. They can be both stationary and mobile with various

Pre Shredder

2022-03-03Pre-shredders are designed for the initial stage of multi-stage shredding systems, aimed at the preprocessing of large-volume, unclassified, mixed, or densely compacted materials. This helps reduce the workload on downstream shredding systems, minimizes wear and tear, and contributes to improved production line throughput and stability.The primary task of pre-shredders is to achieve uniform processing of material flow and are not capable of shredding materials into small sizes. They typically collaborate with shear shredders to ensure that the waste stream attains specifications suitable for subsequent processing.GEP ECOTECH pre-shredder is a heavy-duty dual-shaft equipment that can easily cope with the challenges posed by large flows of unsorted materials and large-volume materials. They are recommended for processing a wide range of materials, including municipal solid waste, construction and demolition debris, bulky waste, landfill waste, mixed waste, scrap vehicles, and metal packaging. GEP ECOTECH pre-

Four-Shaft Shredder

2022-03-03Four-shaft shredders are designed to process challenging materials into uniform sizes in a single pass. Compared to dual-shaft shredders, they feature two additional auxiliary shafts for extra shearing force, and the classifier screen that allows to define the output size.Maintaining four-shaft shredders poses a significant challenge, particularly when it involves replacing or repairing the bottom blades. This intricate process demands highly skilled technicians with specialized tools and can extend over many hours.GEP ECOTECH four-shaft shredders are suitable for most size reduction and heavy-duty applications. We recommend using them for handling complex materials and when there are strict output size requirements for single-stage shredding.GEP ECOTECH four-shaft shredders are renowned for their robust construction and powerful drive shafts. We utilize top-tier materials to enhance blade longevity and equip them with robust electrical or hydraulic drives, along with an intelligent control system. This

Double-Shaft Shredder

2022-03-03Double-shaft shredders are designed to process flexible and ductile materials, breaking them down for purposes such as destruction, volume reduction, or recycling. Operating at low speeds, these shredders provide exceptional cutting force to handle challenging materials while maintaining very low levels of noise and dust.The most significant challenges faced by double-shaft shredders are the complex working conditions and ever-changing materials. They operate in harsh environments where material streams are constantly shifting and sometimes unpredictable. Insufficient torque can lead to the equipment's inability to complete tasks, sometimes resulting in continuous reversing, wasting energy. Conversely, excessive torque without proper machine performance matching can lead to significant accidents, including catastrophic failures like shaft breakage.With outstanding design concepts, robust raw material selection, exquisite manufacturing craftsmanship, and continuous optimization of control software, GEP