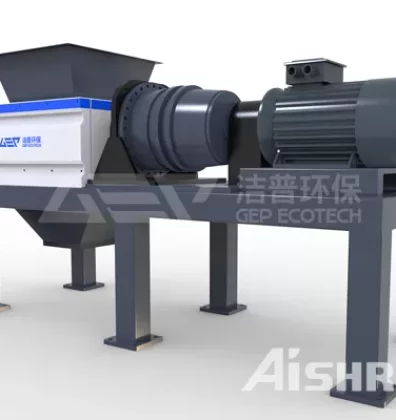

Recently, a client from Africa visited GEP ECOTECH to explore advanced solid waste shredding solutions. Having used Lindner single-shaft shredders for years to process plastic films and blocks, the client found their existing equipment could no longer meet increasing capacity and efficiency demands. After touring GEP ECOTECH's facility and seeing the GSE series European version single shaft fine shredder in action, they were impressed by its smart features, robust design, and overall performance—recognizing it as a strong alternative to their current Lindner system.

Key Advantages of the GSE Series European Version Single Shaft Fine Shredder

The GSE series combines advanced engineering, robust design, and intelligent control systems to deliver next-level performance and reliability. Its core advantages include:

High Power Output and Superior Throughput

Driven by motors ranging from 90kW to 220kW, the shredder can process a wide range of plastic and solid waste materials. Depending on the type of material, screen configuration, and output size requirements, the throughput can reach up to 10 tons per hour, making it an ideal solution for heavy-duty applications.

Adjustable Discharge Size

The shredder features a hydraulically operated screen drawer for quick and convenient mesh replacement. Discharge sizes range from 50mm to 100mm, allowing users to fine-tune the output according to specific downstream process needs.

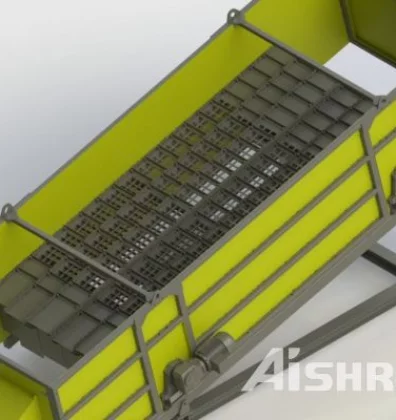

High-Durability Cutters

Fitted with imported high-strength alloy steel blades, the cutting system offers excellent wear resistance and impact strength. The “V”-shaped rotor cutter arrangement creates a continuous shearing angle with the stator cutters, significantly enhancing cutting efficiency and producing uniform shredded material, while extending cutter life.

Optimized Structure for Easy Maintenance

The hydraulic screen opening system simplifies maintenance and cleaning. The suspended gearbox design delivers high torque with a compact footprint, improving transmission efficiency and reducing energy consumption while ensuring stable operation.

Intelligent Control via GI System

Equipped with GEP ECOTECH's proprietary GI intelligent system, the shredder supports automatic lubrication, real-time condition monitoring, fault alarms, and intelligent foreign object protection. This reduces the need for manual intervention and enhances operational safety and maintenance efficiency.

Multiple Solutions for Shredding Plastic Waste

GEP ECOTECH offers a complete range of shredding technologies tailored for different plastic types and processing requirements. From lightweight packaging materials to complex composite plastics, we provide optimized solutions including:

Double-Shaft Shredders: Ideal for rigid plastics, engineering plastics, and composite plastics containing metals. Offers powerful shear force and is suitable for primary size reduction.

Four-Shaft Shredders: Designed for bulky, flexible materials like jumbo bags, woven sacks, and stretch film. Features high anti-wrapping capacity and consistent output particle size.

Plastic Granulators: Engineered for thin-walled and lightweight plastics such as PET bottles, PE films, and PP woven bags. Delivers fine output sizes ranging from 2mm to 30mm, perfect for pre-treatment before regranulation.

GEP ECOTECH provides equipment solutions customized to your specific needs regarding throughput, discharge size, energy efficiency, and automation. With the integration of the GI intelligent platform, our systems support remote operation, smart diagnostics, and automated maintenance—helping clients maximize output while minimizing operational cost.

As a professional solid waste disposal equipment manufacturer, GEP ECOTECH provides tailored equipment configurations and system solutions for various plastic materials and treatment requirements. If you have relevant needs, feel free to contact us.