In the face of rising plastic waste, especially lightweight and flexible materials like PET bottles, PE films, and PP woven bags, the need for reliable, small-scale shredding equipment is growing rapidly. GEP ECOTECH's small shredder machine for plastic is engineered to provide a compact, cost-effective, and efficient solution for processing various soft and rigid plastic wastes, making it an ideal choice for recyclers, manufacturers, and community-based sorting facilities.

Versatile Applications Across Plastic Waste Streams

GEP ECOTECH's small plastic shredder is suitable for handling a wide variety of plastic waste streams, including PET bottles, PE films (such as stretch film, agricultural film, and plastic bags), and PP woven bags, as well as other rigid plastics like small containers, pipes, caps, and trays. This flexibility makes it an ideal solution for use in plastic recycling plants, film and packaging waste stations, injection and extrusion waste recovery lines, community recycling centers, small workshops, and even R&D or educational labs where controlled plastic size reduction is required.

Ideal Output and Capacity

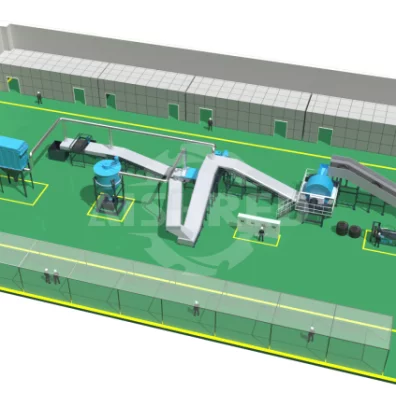

The machine produces uniform plastic granules with a discharge size of approximately 2-10 mm, controlled by adjustable screens. With a processing capacity range of 100 to 1300 kg/h, it provides excellent flexibility for small to medium-scale recycling operations. Whether used as a standalone unit or integrated into a larger recycling line, it ensures reliable throughput and consistent output quality.Compact, Practical, and Easy to Operate

Despite its small footprint, the machine features a robust rotor, high-quality blades, and a standard electrical control cabinet supporting basic functions such as start/stop, reverse, and overload protection. It's simple to operate, easy to maintain, and offers great value for facilities seeking to reduce plastic waste without the complexity or cost of large-scale systems. Blade maintenance and cleaning are quick thanks to a modular design.

Other Options for Plastic Waste Recycling

The equipment discussed above mainly focuses on soft and small-sized plastic materials. If you need to process larger, tougher plastics—such as barrels, sheets, or thick-walled components—GEP ECOTECH also offers heavy-duty alternatives like double-shaft plastic shredders and single-shaft shredders, engineered for higher loads and more demanding applications.

After shredding, plastic waste can be repurposed in several ways depending on the material and processing goals. It can be further processed into recycled plastic granules for use in manufacturing, utilized as refuse-derived fuel (RDF/SRF) for thermal energy recovery, or even converted into fuel oil and gas via pyrolysis, supporting sustainable and efficient waste-to-energy transformation.

GEP ECOTECH's shredding equipment provides the essential front-end processing needed for all of these applications, ensuring stable size, clean output, and compatibility with granulators and other recycling systems.

Powered by GEP ECOTECH

As a trusted leader in solid waste recycling technologies, GEP ECOTECH combines intelligent design, reliable engineering, and responsive service in every product we deliver. Our small plastic shredder is built to help businesses reduce plastic waste volume, improve material recovery rates, and support circular economy practices with a machine that’s compact in size—but powerful in impact.

Contact GEP ECOTECH today to learn how our plastic shredding solutions can boost your recycling capability while saving space, cost, and effort.