With growing environmental awareness and the global shift toward sustainable energy, RDF (Refuse Derived Fuel) is gaining traction across industries. TDF (Tire Derived Fuel), a significant branch of RDF, is increasingly valued for its ability to transform waste tires into valuable fuel. By shredding scrap tires into small pieces (typically around 50mm), TDF can partially replace fossil fuels in high-energy industrial operations like cement kilns and power plants—reducing environmental impact while promoting resource recovery.

To meet varying application needs and investment levels, GEP ECOTECH offers two tailored tire shredding solutions:

Integrated Slicing and Dicing Machine

Main Advantages:

- Compact Design, User-Friendly: The all-in-one structure is space-saving and easy to operate, allowing quick deployment with minimal training.

- Low Entry Cost: Ideal for small and medium-sized investors, this solution reduces upfront investment and accelerates market entry.

- Tailored for Moderate Capacity: Perfect for projects with moderate processing needs or for businesses starting in the tire recycling industry.

- Targeted Tire Size Compatibility: Designed to process tires up to approximately 1.2 meters in diameter, matching specific operational requirements.

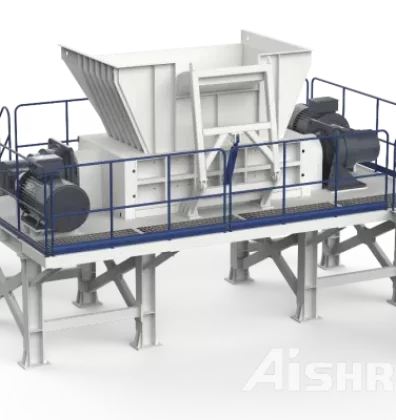

Industrial-Grade Tire Shredder

Main Advantages

- High Efficiency Shredding: Equipped with a double-shaft system and sharp cutters, it quickly reduces tires to uniform size, maximizing productivity.

- Versatile Processing: Handles various tire types and sizes—from car to truck tires—with ease, meeting diverse processing demands.

- Durability and Longevity: Made with wear-resistant alloy steel components, the shredder offers long service life and low maintenance costs.

- Smart Control System: Features intelligent monitoring for stable and efficient operation with real-time performance insights.

- Designed for Large-Scale Production: Ideal for enterprises with high processing volumes, offering strong throughput and economic returns.

Each solution comes with distinct strengths. Whether you’re a newcomer to tire recycling or managing large-scale production, GEP ECOTECH can help you select the optimal equipment based on your budget, scale, and tire types. Reach out to us for customized recommendations that turn waste tires into valuable fuel.