In the sand, aggregate, mineral processing, and construction waste recycling industries, the jaw crusher, as the core equipment in the primary crushing stage, directly impacts the production line's efficiency, finished product quality, and long-term operating costs. The traditional PE series jaw crushers and the European-style jaw crushers developed based on modern crushing theory represent two distinct technological paths. This article aims to provide a professional basis for equipment selection through a systematic technical comparison of the two.

Fundamental Differences in Design Philosophy and Structural Evolution

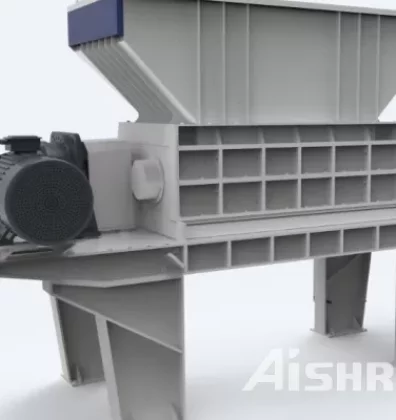

The design of traditional PE jaw crushers originates from classic structures, featuring a welded frame, a bottom-mounted eccentric shaft, and a simple swing moving jaw design, emphasizing reliability and manufacturing cost. This design is mature and offers convenient maintenance, but its inherent limitations become increasingly apparent when dealing with high-intensity, high-efficiency modern continuous production.

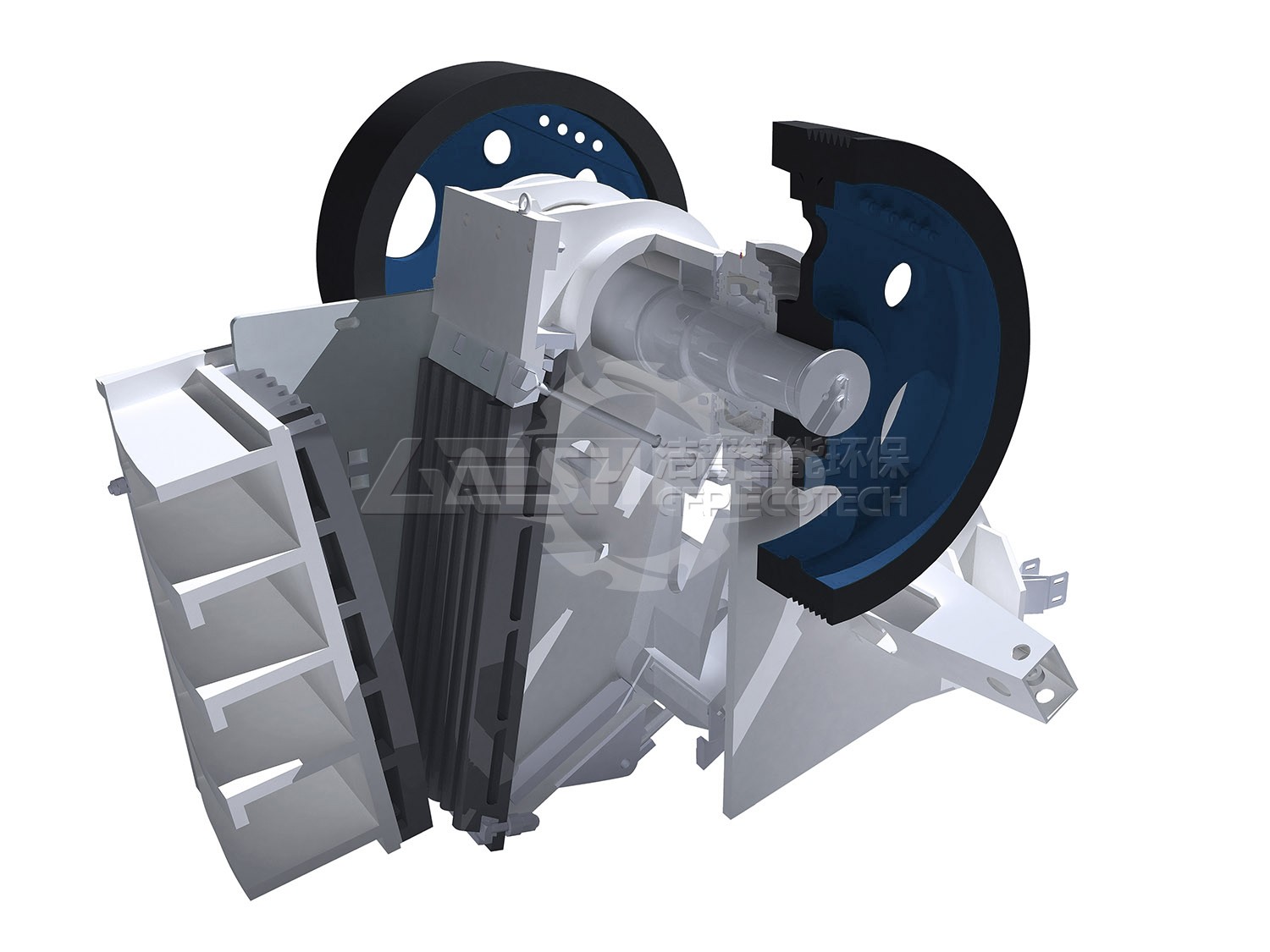

The European-style jaw crusher represents a new generation of design with structural optimization at its core. Its essence lies in the redesign based on mechanical principles, achieving an overall leap in performance. The integrated heavy-duty frame provides unparalleled rigidity and fatigue resistance, laying the physical foundation for withstanding higher crushing forces and impact loads. The most significant innovation is the relocation of the eccentric shaft to the middle-upper part of the machine, combined with a negative suspension or zero-suspension moving jaw design, fundamentally altering the kinematics of the moving jaw.

Core Performance Comparison: Efficiency, Product Quality, and Durability

The most critical difference between the two lies in the moving jaw's motion trajectory, which directly determines the crushing process outcome.

Crushing Efficiency and Processing Capacity

The moving jaw trajectory of traditional PE jaw crushers approximates an ellipse with a relatively large vertical stroke. This causes material to pass through the crushing chamber more via sliding friction, reducing effective crushing work and limiting throughput per unit time. Through optimization, the European-style crusher improves the crushing ratio and feed acceptance capacity, reduces wasteful friction, and concentrates energy more on compressive crushing, thereby achieving higher processing capacity under equivalent power.

Product Shape and Quality

The difference in moving jaw trajectory directly affects product characteristics. Due to its large vertical stroke, the PE jaw crusher subjects material to more grinding action before discharge, tending to produce more needle and flaky particles. As compressive crushing dominates in the European-style crusher, the proportion of cubic aggregates produced is significantly higher, resulting in superior particle shape. This is crucial for producing high-grade concrete aggregate or applications with strict gradation requirements.

Wear Part Life and Operating Costs

Wear on the jaw plates of PE jaw crushers is uneven, particularly severe at the bottom, reducing material utilization. The optimized trajectory of the European-style crusher results in a more uniform wear distribution, significantly extending jaw plate service life. Furthermore, its commonly used modular wedge-type discharge setting adjustment system allows for precise adjustment within minutes, offering safety and efficiency, significantly reducing maintenance downtime, and ensuring the stability of continuous production.

Comprehensive Economic Benefit Analysis

From an investment perspective, the lower initial purchase cost of traditional PE jaw crushers is their main market advantage. However, from a Total Cost of Ownership (TCO) analysis, the advantages of the European-style jaw crusher are more prominent:

- Energy Cost: Higher crushing efficiency means lower energy consumption per unit of output, leading to considerable savings in electricity costs over long-term operation.

- Wear Part Cost: Longer jaw plate and liner life directly reduces the cost of wear parts per ton of product.

- Maintenance and Downtime Cost: The sturdier frame reduces failure risk, and the rapid adjustment mechanism shortens maintenance time, improving equipment utilization.

- Downstream Benefits: Superior product shape can increase product selling price and market competitiveness, and create better conditions for downstream processes like sand making.

PE jaw crushers are suitable for small to medium-sized projects sensitive to investment budgets, processing medium to low hardness materials, with less strict product shape requirements, or serving as primary crushing units. Their value lies in fundamental reliability and economy.

For modern large-scale production lines pursuing high output, stability, and low consumption, especially when processing hard and abrasive materials like granite and basalt, the European-style jaw crusher is a more suitable technological choice. It not only meets the higher standards for production efficiency and product quality but also ensures optimal return on investment over the project's entire lifecycle due to its exceptional durability and low-maintenance characteristics.

GEP ECOTECH, as a jaw crusher supplier with rich industry experience, always takes higher efficiency, lower energy consumption, and superior quality as our development direction. The European-style jaw crusher recommended by GEP successfully addresses the pain points of traditional designs in efficiency, particle shape, and wear through in-depth optimization of structural mechanics and kinematics. Choosing GEP ECOTECH, we provide you with the most economical equipment selection solutions, helping you build production lines with greater core competitiveness.