With the acceleration of urban development and old house renovation, a large amount of construction and decoration waste is constantly being generated. These wastes are complex in composition, including bricks, cement blocks, wood, plastics, flooring scraps, and other lightweight materials. If directly landfilled without scientific treatment, they not only occupy land resources but may also cause environmental pollution. Faced with such complex materials, how can we achieve efficient construction and demolition (C&D) waste recycling? Let's take a closer look.

Key Treatment Processes

1. Crushing—Reducing Material Size for Further Use

The purpose of crushing is to reduce bulky construction and decoration waste into smaller particles suitable for processing and utilization. Common Construction Waste Crushers include:

Jaw Crusher: Reduces the size of stones and ores through extrusion. It can handle large feed sizes, is typically used for primary crushing, offers a large reduction ratio, and works efficiently.

Impact Crusher: Reduces the size of materials using impact force. It is suitable for processing materials with low to medium hardness, commonly applied in primary or secondary crushing, producing particles with uniform size and good shape.

2. Screening—Particle Classification and Impurity Removal

The screening stage classifies particles according to size and removes fine impurities. Common equipment includes:

Circular Vibrating Screen: Uses circular vibration trajectories to stratify and sieve materials. It is suitable for materials with relatively uniform particle size and moderate moisture.

Flip Flow Screen: Designed for moist and sticky materials. Its stretching and loosening movement prevents clogging and ensures screening efficiency under wet conditions.

Depending on the characteristics of the material, other types of screening equipment can also be flexibly applied to achieve optimal classification.

3. Sorting—Separating Light and Heavy Materials

Sorting is mainly carried out using air separators, which rely on aerodynamic principles to separate materials by weight. Lightweight materials such as wood, plastic, and cardboard are separated for RDF fuel production or industrial combustion, while heavy aggregates such as bricks and concrete can be reused as recycled aggregates or fillers, maximizing resource utilization.

Final Products and Applications

1. Bricks, concrete, and other heavy materials: Can be used as recycled aggregates, sub-base materials for road construction, or building fillers.

2. Wood, cardboard, plastics, and other lightweight combustible materials: Can be used for RDF fuel production, realizing energy recovery.

3. Metal materials: Such as steel bars and aluminum, can be recycled for reprocessing and industrial raw materials.

4. Glass and other non-metallic materials: Can be recycled as fillers in building materials or for other industrial applications.

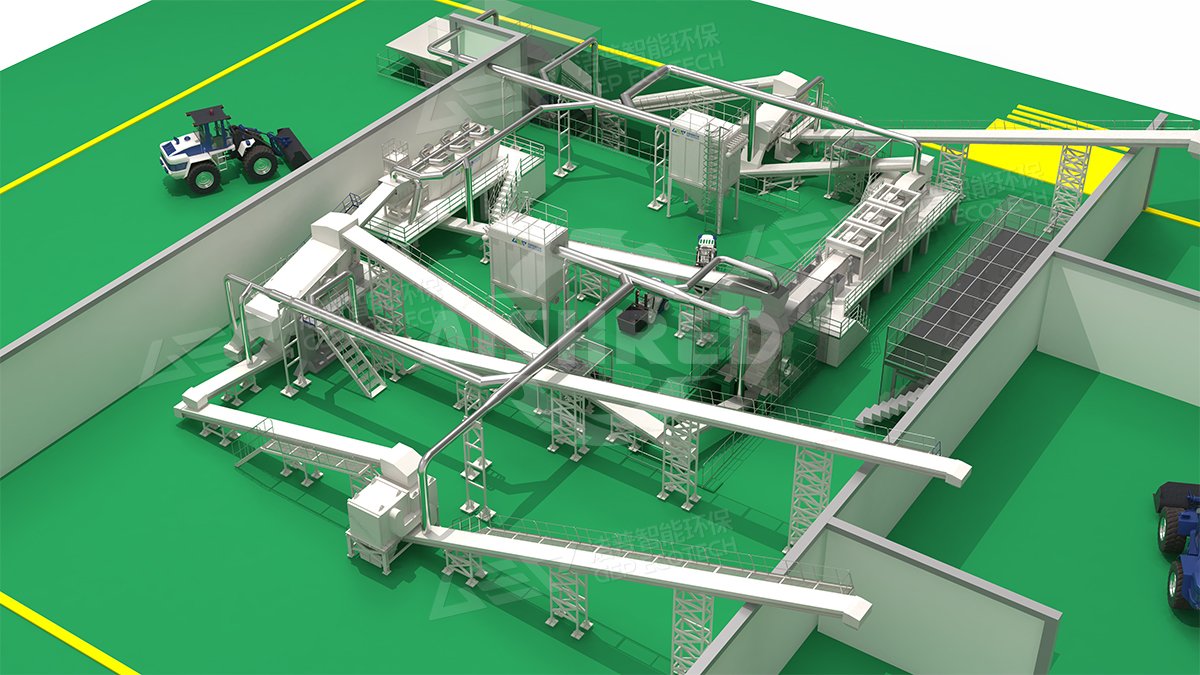

Customized Disposal Process

Based on years of experience in C&D waste management, GEP ECOTECH has developed an integrated solution that combines crushing, screening, and sorting. We also provide tailor-made solutions according to actual material conditions and customer requirements, enabling efficient, safe, and environmentally friendly C&D waste recycling. Feel free to contact us—turn waste into valuable resources and achieve a win-win outcome of economic benefits and environmental value!