Choosing between impact crushers and cone crushers in the mining and construction waste disposal industry is a critical decision that impacts investment, operational costs, and final product returns. First, let's clearly define their roles: both are typically used in the second and third stages of crushing, positioned after jaw crushers (primary crushing). We will provide a detailed analysis of their applications and selection recommendations from three aspects: principles, advantages and suitable scenarios.

Impact Crusher

Working Principle:

The impact crusher utilizes impact energy to break materials. The high-speed rotating rotor drives the hammer plates, striking the material entering the crushing chamber. The material gains kinetic energy and is thrown toward the impact plate for further collisions. Simultaneously, the material particles collide with each other repeatedly until they meet the required particle size and are discharged through the outlet.

Advantages:

- Excellent finished particle shape: Due to the impact crushing and collision between materials, the produced aggregates mostly exhibit a cubic form with distinct edges, resulting in superior particle shape. This is crucial for high-grade concrete and asphalt aggregates, as it enhances the compressive strength and stability of the product.

- Flexible adjustment of discharge particle size: By regulating the rotor speed and the clearance between the impact plate and the hammer, the discharge particle size can be conveniently modified, enabling multi-functional use with high flexibility.

- Low investment cost: For the same processing capacity, the initial purchase cost of impact crushers is generally lower than that of cone crushers.

- Low powder rate: It delivers excellent crushing performance for low to medium hardness materials such as limestone, dolomite, and construction waste (concrete blocks, bricks, and tiles).

- Excessive crushing is minimal, and the powder ratio is relatively low: when processing medium-hard materials, the resulting stone powder is less than that produced by cone crushers.

Cone Crusher

Working Principle:

The cone crusher adopts the laminating crushing principle. The moving cone eccentrically rotates within the fixed cone, causing the material to be crushed through repeated compression, impact, and bending within the crushing chamber formed by the moving and fixed cones. The material passes through multiple crushing stages from top to bottom before being discharged.

Advantages:

- Wear resistant parts have a long lifespan and low operating costs: Using laminated crushing, wear-resistant parts (rolling bowl wall and crushing wall) do not directly impact the material, but slowly apply pressure, resulting in minimal wear. When crushing high hardness materials, the lifespan of their wear-resistant parts is much longer than that of the impact hammer, resulting in lower long-term operating costs.

- Low energy consumption: The efficiency of extrusion crushing is higher than that of impact crushing, and the energy consumption per unit output is usually lower.

- Large and stable output: Suitable for large-scale, continuous production lines, with very strong and stable production capacity.

- Suitable for high hardness materials: It is the preferred choice for crushing high hardness materials such as granite, basalt, and river pebbles.

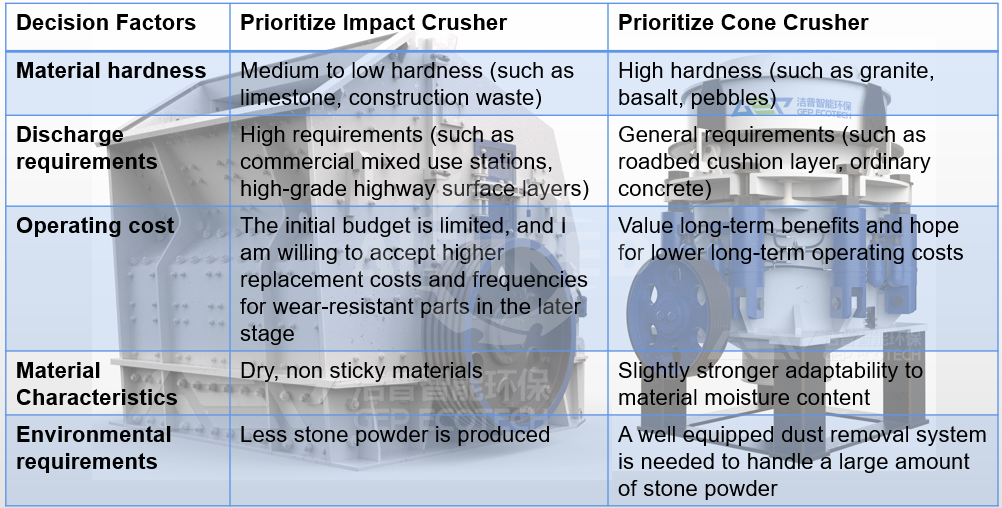

How to Make Decisions?

You can decide which device to choose based on the following key questions:

For the disposal of construction waste, priority should be given to impact crushers

Material characteristics: The hardness of construction waste (demolished concrete, bricks and tiles) generally belongs to the medium to low level, which is very suitable for crushing with impact crushers.

Product value: Recycled aggregates from construction waste are commonly used in the production of recycled bricks, roadbed materials, etc. They have certain requirements for particle size, and cube aggregates produced by impact crushers can improve product quality.

Impurity removal ability: The impact crusher can better separate impurities such as steel bars and wooden blocks wrapped in concrete during the crushing process, which is beneficial for subsequent sorting.

Flexibility: The composition of construction waste is complex, and the particle size of incoming materials is uneven. The impact crusher has better adaptability.

For the mining industry

If the stone material is high-hardness rock, the "jaw crusher + cone crusher" solution should be chosen without hesitation. This is the most economical, efficient and stable option. If the rock is of medium hardness and the shape of the aggregate is highly required (such as as the base material for manufactured sand), a "jaw crusher + impact crusher" can be considered.

GEP ECOTECH has rich experience and numerous successful cases in the field of mining and construction waste recycling. Our powerful technical team will based on your material conditions and discharge effect requirements, estimate energy consumption and wear data to provide you with the best choice for balancing investment costs.