Crop straws, like other agricultural and forestry wastes, are widely used biomass energy. Using them as fuel for biomass power plants is one of the popular options. There are many advantages to using crop straws to generate electricity. They usually have a high calorific value, can enter the boiler without complicated treatment, and do not consume carbon emission quotas.

To use crop residues and other biomass materials to generate electricity or heat, they just need to be processed to a size suitable for combustion.

It's simple, yet challenging. The main reason is that the boiler cannot be turned off, and the fuel must be continuously and stably supplied

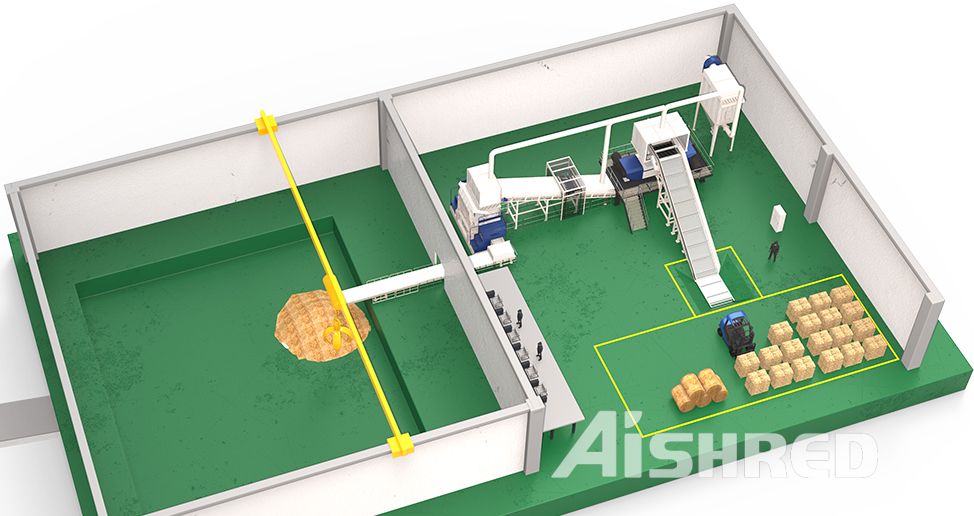

Using the GEP ECOTECH biomass pretreatment system, you can draw on our many years of experience in this field. The system is composed of biomass shredder, chain plate conveyor, belt conveyor, magnetic separator, intelligent monitoring system, and dust collector. It can process biomass raw materials to suitable uniform sizes according to recycling needs. The overall intelligent processing ability of the system is strong, and the shredding efficiency is high, which can meet the requirements of long-term stable operation.

Biomass Disposal Process

The collected biomass raw materials are sequentially fed into a double shaft shredder on a chain conveyor, and then pushed into a cutter box by a hydraulic pusher above for shredding treatment. Due to the use of intelligent feeding, the conveyor can automatically adjust the feeding speed according to the load of the main motor, ensuring a continuous and sufficient supply of raw materials, avoiding equipment blockage and other failures caused by the accumulation of wet raw materials at the shredder warehouse. The shredded materials are concentrated and collected on a discharge conveyor for output.

Advantages of the Solution

The advantage of this disposal process lies in the intelligent adjustment of motor load by the selected double shaft shredder, which can ensure the long-term operation of the entire processing line and stably produce biomass fuel that meets the size required for boiler incineration.

- Intelligent feeding + hydraulic pressing + large capacity working area, with sufficient supply, smooth feeding, and high processing efficiency;

- The equipment adopts an integral cutter box, high-strength cutter shaft, and high wear-resistant cutters, which are sturdy, durable, and have a long service life;

- The intelligent monitoring system monitors and protects the temperature, pressure, and operation of various subsystems such as motors, bearings, and hydraulic systems in real-time, maintaining low energy consumption and low operating costs;

- The centralized intelligent lubrication system ensures that the oil in the bearings is always in sufficient condition, avoiding downtime caused by bearing damage, and ensuring stable equipment operation.

In short, biomass straw is an important agricultural waste resource, and through reasonable treatment and utilization of straw, it can make positive contributions to the ecological environment and rural economic development.