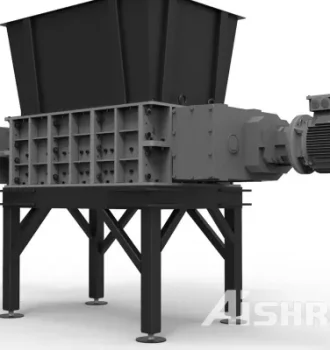

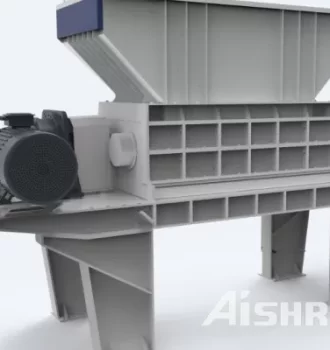

With the rising number of end-of-life vehicles (ELVs) worldwide, the recycling of automotive shells has become a strategic necessity in the resource recovery and green manufacturing sectors. Automotive body shells are typically composed of high-strength steel, aluminum, copper, plastic composites, insulation materials, and more. Efficient separation and recovery of these materials can generate significant economic and environmental benefits.GEP ECOTECH provides a powerful, modular solution for ELV shell recycling, integrating advanced shredding, optional hammermill shredder, and precise separation technologies to help customers maximize material recovery while reducing operating costs.Shredding First: Dual-Shaft Shredder for Efficient Size ReductionThe recycling process begins after basic dismantling of the ELV. The remaining shell is fed into GEP ECOTECH’s heavy-duty dual-shaft shredder, designed to tear down car bodies, reinforced panels, doors, and engine compartments with high torque and wear-resistant

A new metal crushing and sorting line has begun trial operation in central China. This advanced production line integrates various high-efficiency equipment, including a metal shredder, magnetic separator, eddy current separator, air classifier, dust removal system, and other components, capable of processing around 15 tons of metal waste per hour. The line is designed to transform complex scrap metal into high-quality secondary raw materials through a multi-step process.The core of this line is the metal crusher, which is responsible for breaking large scrap metal into smaller, recyclable pieces. Following crushing, the magnetic separator and eddy current separator efficiently separate ferrous and non-ferrous metals, ensuring accurate material classification. The air classifier is used to remove lighter impurities, ensuring the purity of the final product. Meanwhile, the dust removal system significantly reduces dust emissions, meeting environmental standards.The processed product consists of clean, small

Recently, we received exciting news from our South Korean customer: the GD9Q dual-shaft shredder we supplied has been officially put into operation for scrap metal shredding.The customer, a prominent metal recycling company, handles a variety of scrap metals, including copper-clad laminate, circuit boards, copper-coated steel waste, and copper shavings. They use our GD9Q shear shredder to reduce these materials into pieces of about 10 cm for further processing.The GD9Q is an enhanced version of the GD9, specifically designed to deliver greater shearing force and durability for demanding applications. The installation process was supported by GEP ECOTECH’s technical team, ensuring a smooth and efficient setup.This project is one of the many successful metal recycling projects recently executed by GEP ECOTECH. In the current global economic downturn, many environmental projects dependent on government investments or subsidies have been delayed or canceled. However, metal recycling remains a lucrative

With the continuous development of industrialization, the disposal of scrap metal has gradually attracted people's attention. Scrap metal shredder as an efficient, environmentally friendly processing equipment, has gradually become the first choice in the field of scrap metal processing.First of all, the scrap metal shredder has a very high processing efficiency. Through the powerful shredding force, the scrap metal can be quickly shredded into small particles, greatly reducing the processing time. At the same time, the shredded metal particles are easier to store and transport, providing convenience for subsequent processing.Secondly, the scrap metal shredder has significant environmental advantages. The traditional way of handling scrap metal often produces a large amount of pollution, posing a threat to the environment and human health. The scrap metal shredder, on the other hand, adopts advanced low-noise, low-emission design, which effectively reduces the environmental pollution in the treatment process

When it comes to metal processing and waste management, the Hammermill Shredder is an essential piece of equipment. It is widely used for shredding discarded metal materials such as automotive wreckage, discarded electronic devices, and other metal scraps into smaller particles for further recycling or disposal.Working Principle of the Hammermill ShredderThe Hammermill Shredder operates based on a set of rotating hammers that crush metal materials at high speeds. It shreds metal waste into smaller particles through impact and shear forces. The primary function of a Hammermill Shredder is to reduce large metal pieces into smaller, manageable fragments. It is particularly effective in breaking down bulky metal waste, such as automotive parts or appliances, into smaller particles. Hammermill Shredders typically have a single rotor with multiple hammers mounted on it. The hammers strike the metal waste as it passes through, resulting in fragmentation. Hammermill Shredders are commonly used in the initial stages

UBC stands for Used Beverage Cans, and as the name suggests, it primarily consists of aluminum beverage containers that have been consumed and discarded by consumers. These cans are commonly used for packaging various beverages, including cocal, soda, beer, and energy drinks. UBC originates from households, commercial establishments, and public spaces, where people consume these beverages and then empty cans are collected by recycler.The recycling value of UBC is substantial and multifaceted. Aluminum, the primary metal in UBC, is highly sought after in the recycling industry for several reasons. Firstly, recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. This energy efficiency translates into reduced greenhouse gas emissions and conserves valuable resources. Secondly, aluminum retains its quality and properties even after multiple recycling cycles, making it an ideal material for sustainable manufacturing. Lastly, the recycling of UBC reduces the

Scrap Metal Shredder for Sale Australia

2023-12-14Australia has a strong focus on metal recycling, a growing industry where these metal resources are recycled for remanufacturing, construction and other industrial uses. Metal shredders are an essential piece of equipment for metal recycling, so what are the metal shredders on sale in Australia? Let's take a look at a typical metal recycling project in Australia.Introduction to GEP's Australia Metal Recycling ProjectThis project is a solid waste treatment and recycling project invested by Australia's leading aluminum material production and processing company. This production line integrates three common metal shredding equipment (coarse shredder, medium shredder, double-shaft shredder, fine single-shaft shredder) and high-efficiency sorting equipment (magnetic separator, eddy current Sorting machine and trommel screen). The entire production line has practical technology, strong functionality, and high utilization rate of scrap metal resources.Metal Recycling Project in Australia Australia Metal Shredders

Large Scale Aluminium Recycling Plant

2023-11-16A large-scale aluminum recycling plant involves advanced processes and equipment to efficiently recycle significant volumes of aluminum scrap. Here's an overview of the key components and processes typically found in such facilities:Collection and Sorting:Material Procurement: Collect aluminum scrap from various sources, including manufacturing waste, post-consumer products, construction materials, and automotive parts.Automated Sorting Systems: Employ advanced sorting technologies such as electromagnetic separators, eddy current separators, and optical sorting machines to segregate different aluminum alloys, forms, and contaminants.Shredding and Processing:Shredding and Shearing: Utilize heavy-duty shredders, shears, or granulators to process large aluminum items into smaller fragments or chips, optimizing for melting efficiency.A large-scale aluminum recycling plant integrates advanced technologies and processes to handle substantial volumes of aluminum scrap, contributing significantly to resource

Aluminum scrap is a waste generated during the production of aluminum products, and its effective treatment is crucial for resource recovery and environmental protection. In the aluminum chip pretreatment stage, the dual-shaft shredder shows its unique advantages and becomes an efficient and stable aluminum chip processing tool.Structure and working principleStructural design: The aluminum chip twin-shaft shredder consists of two parallel rotating main shafts, each of which is equipped with a strong shredding blade. This dual-axis design allows aluminum chips to be shredded in multiple directions and evenly in two interacting shredding systems.Working principle: During operation, aluminum chips enter the dual-shaft shredder through the feed port and are sheared and shredded by the blades on the dual shafts. Due to the relative motion of the two shafts, the aluminum chips are shredded multiple times between the two shafts, thereby achieving an efficient and detailed shredding effect.Applicability and advantage

Zorba Sorting and Recycling Plant for Sale

2023-06-09"Zorba" is a non-ferrous metal scrap that is separated by eddy current separators in the metal recycling process and is mainly composed of aluminum and may also contain copper, nickel, zinc, alloy materials or other non-metallic scrap. Zorba usually comes from the recycling process of end-of-life vehicles, waste electrical and electronic equipment and other kinds of waste. AIShred Metal Recycling Solutions can provide shredding and sorting of various scrap metal materials including Zorba. AIShred Recycling Solutions cover almost all kinds of solid wastes. Our equipment is being used in many recycling facilities around the world. Whether it is material recovery or energy recovery, our equipment can perfectly meet the design requirements and complete the task excellently. Choose AIShred to improve production efficiency, reduce energy consumption, and help your waste mining business run reliably for a long time. We are ready to provide any possible support for your business planning at any time, please leave

Scrap Metal Processing

2022-03-03Metals are one of the most widely used materials on earth and are a non-renewable resource, consisting mainly of non-ferrous metals (aluminum, copper, zinc, etc) and ferrous metals (iron, manganese, chromium, etc), which are made into a variety of alloyed monomers and alloyed products that are widely used in production and life.Most metals have a huge recycling value and with GEP ECOTECH's metal shredding plants metal products can be efficiently crushed and sorted for transport and subsequent smelting. GEP ECOTECH's shredding solutions are used for sheet metal, drums, stampings, turned parts, metal molds, aluminum products, radiators, copper wire, metal pipes, as well as special alloys, car casings, auto shredder residue, scrap metal briquettes, lead-acid batteries, etc. for shredding and recycling.Please note that heavy sheet metal, metal castings etc. are not handled by GEP ECOTECH equipment.