UBC stands for Used Beverage Cans, and as the name suggests, it primarily consists of aluminum beverage containers that have been consumed and discarded by consumers. These cans are commonly used for packaging various beverages, including cocal, soda, beer, and energy drinks. UBC originates from households, commercial establishments, and public spaces, where people consume these beverages and then empty cans are collected by recycler.The recycling value of UBC is substantial and multifaceted. Aluminum, the primary metal in UBC, is highly sought after in the recycling industry for several reasons. Firstly, recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. This energy efficiency translates into reduced greenhouse gas emissions and conserves valuable resources. Secondly, aluminum retains its quality and properties even after multiple recycling cycles, making it an ideal material for sustainable manufacturing. Lastly, the recycling of UBC reduces the

The recycling of PVC window frames plays a crucial role in sustainable waste management, with a focus on resource recovery and environmental conservation. This article explores the efficient process of shredding PVC window frames to extract valuable steel and aluminum, contributing to a more circular and eco-friendly approach to materials management.Shredding ProcessThe initial step in recycling PVC window frames involves the use of advanced shredding equipment. A high-capacity industrial shredder is employed to break down the window frames into smaller, more manageable pieces. The shredding process not only reduces the volume of materials but also prepares them for subsequent separation and extraction stages.Steel Extraction:Once the PVC window frames are shredded, the material undergoes a separation process to extract steel components. This is often achieved through the use of magnetic separators, which attract and isolate ferrous metals like steel. The extracted steel components can then be sent to steel

Zorba Sorting and Recycling Plant for Sale

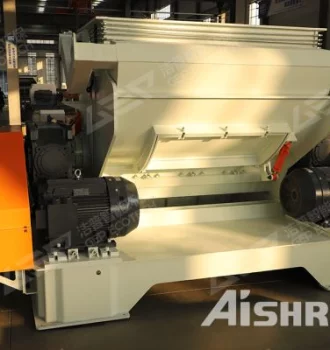

2023-06-09"Zorba" is a non-ferrous metal scrap that is separated by eddy current separators in the metal recycling process and is mainly composed of aluminum and may also contain copper, nickel, zinc, alloy materials or other non-metallic scrap. Zorba usually comes from the recycling process of end-of-life vehicles, waste electrical and electronic equipment and other kinds of waste. AIShred Metal Recycling Solutions can provide shredding and sorting of various scrap metal materials including Zorba. AIShred Recycling Solutions cover almost all kinds of solid wastes. Our equipment is being used in many recycling facilities around the world. Whether it is material recovery or energy recovery, our equipment can perfectly meet the design requirements and complete the task excellently. Choose AIShred to improve production efficiency, reduce energy consumption, and help your waste mining business run reliably for a long time. We are ready to provide any possible support for your business planning at any time, please leave

A Chinese recycling company named Central Plains Environmental Protection(CPEP) operates a recycling plant planned and implemented by AIShred - designed for processing various materials such as automotive shredder residue (ASR), electrical and electronic scrap (WEEE) and selectric motors and motor armatures. The process developed together with the company is based on an economic analysis and ensures marketable end products. As part of capacity expansion efforts, CPEP choses a facility that would allow them to process different materials simultaneously at their six-acre site. These include ASR, electrical and electronic scrap, metal composites and meatballs. After AIShred had created an initial concept for a system, extensive tests were carried out in the Yuanyang Test Center with around two to three tons of each of the customer's materials. Based on the experimental data Customers need valid data for their decisions before investing in a new recycling plant. During the tests and analyzes in the test center,

Automobile Shredder Residue(ASR) Recycling

2022-05-09Auto shredder residue (ASR), also referred to as auto shredder fluff, shedder light fraction (SLF), residues from shredding (RESH) or simply “auto fluff” of “fluff”, is the fraction of an shredded end-of-life vehicle (ELV). In the past, it was landfilled. Now, They can now be sorted and recycled thanks to AIShred's sorting and shredding technology. It can prevent this useful and valuable material from taking up the dwindling space in landfills and contribute to a cleaner, safer environment. How ASR Produced?A discarded car is first partially dismantled. All liquids (oils, antifreeze, fuel, etc.) are removed from it. Batteries, tires and catalytic converters are also removed and sent for further processing. Depending on demand, other good parts can be dismantled and sold for use as spare parts. On average, about 10% of the car's weight is pre-dismantled. In a shredder, a car body is shattered into pieces the size of a fist. 70-75% of the various metals from the body are sorted and sold to smelters and