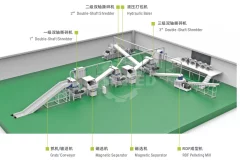

Why Choose Alternative Fuels for Cement Kilns?Fossil fuels (coal) are limited and non-renewable resourcesUsing alternative fuels reduces carbon dioxide emissionsAlternative fuels lower the processing cost of cement productionThere is an increasing need to manage industrial and municipal waste (landfilling is not a sustainable solution)Compared to other industrial consumers, cement kilns are capable of handling a larger volume of difficult-to-treat wasteGEP's Two Alternative Fuels Production SolutionsSolution 1: Three-Stage Double-Shaft ShredderAdvantages:The entire system—covering shredding, conveying, sorting, and shaping—is modular in design, allowing for a more compact and rational layout.Automated operation significantly reduces manual labor, improves production efficiency, and lowers operating costsThe resulting RDF fuel rods are stable in composition and form, featuring high density, high calorific value, and high quality, with a stable market demand.Solution 2: Double-Shaft Shredder + Wind Sifter +

Waste textile materials are highly favored for their high calorific value, uniformity, purity, and low ash content, making them a popular choice for producing RDF alternative fuels. Among the essential equipment, the single-shaft shredder plays a critical role in the process of converting waste textiles into RDF fuel. Advantages 1. High Shredding EfficiencyThe single-shaft shredder features a rotating shaft as its core component, utilizing the shearing and tearing action between high-speed rotating blades and fixed blades to break down materials. This design is particularly suitable for processing fibrous waste textiles, enabling rapid shredding into smaller fragments. The close coordination between the moving and fixed blades ensures thorough shearing and tearing of fibers, minimizing tangling and blockages, thereby significantly improving shredding efficiency. This high-performance shredding capability makes the single-shaft shredder an ideal choice for waste textile processing. 2. Uniform and Controllable

As wind power technology has evolved, the length of wind turbine blades has gradually grown to capture more wind energy. Back in 2014, researchers in the UK surveyed more than 500 wind farms and found that older WTGs built in the 1990s were still producing 3/4 of their power after 19 years. They concluded that most WTGs should be able to run longer than expected, around 25 years before needing to be upgraded.However, as we all know, at some point even the best things must come to an end. While the key to moving the wind industry forward is to continue to reap the benefits of clean energy, there is also a need to consider what to do with the units when they are retired. While the number of retired WTGs worldwide is still low, it will continue to grow as the wind industry expands on a large scale.Fortunately, most WTG components are recyclable, including foundations, towers, gearboxes and generators. WTG blades, however, are difficult to recycle due to their composition.Most WTG blades are composed of

With the rapid development of leather industry, a large number of leather offcuts also caused serious waste of resources and environmental pollution. Especially in the textile, garment, footwear industry is more developed areas, industrial parks pile of leather, cloth offcuts everywhere, bringing serious environmental problems, social problems and government burden. The tannery industry produces a large amount of waste rubber raw materials every year. As a traditional industry with high input and low output, 30% of raw materials in the tanning industry end up as waste in its production process. According to statistics, India discharges about 150,000 tons of tanning waste every year, and the United States has 60,000 tons. And China is a big tanning country, throwing in nearly 200 million pieces of leather every year, which will produce 1.4 million tons of waste. Every year, there are a lot of leather, fabric, shoes, fabric offcuts are casually discarded, which not only causes serious environmental pollution,

With the development of the economy, the number of waste textiles eliminated by residents has gradually increased, sporadic treatment cannot meet the production requirements, and a sustainable industrial waste system is urgently needed to help us explore together. Today, let's talk about the energy recovery of waste textiles. Because of the addition of comprehensive materials, the thermal value of the waste textiles is very good and the combustion is good. Therefore, it has great potential for incineration power generation and cement kiln. As the energy recovery of waste textiles, we must use industrial waste shredding to deal with the production line. Only through the disposal of this production line can we meet the energy recovery of waste textiles. So what is this industrial waste system? First of all, the core equipment of this system is shredding+sorting, and the connection system is conveying. The purpose of broken is to fully shatter, shear and crushed materials. First, ensure that the material can be

With the improvement of people's living and consumption, the use cycle of textiles is becoming shorter and shorter, and the recovery, treatment and utilization of waste textiles have reached a point that cannot be ignored. AISHRED focuses on solid waste crushing equipment, and has its own unique disposal plan for the recycling and reuse of various solid waste, including waste textiles. Now let's briefly discuss the recycling methods of waste textiles.Sources of Textile WastesThe so-called waste textile mainly refers to the waste short fiber, waste yarn, silk return, leftover material, etc., as well as the waste textile clothing and its products produced in the production process. Waste textiles mainly come from two aspects: one is from production enterprises, which will produce waste staple fiber, waste yarn, silk return, waste cloth noil, etc. in various processes of spinning, weaving and finished product production and processing. On the other hand, it comes from discarded textiles in daily life, such as

Energy Recovery from Municipal Solid Waste

2022-06-06Municipal Solid Waste (MSW) contains organic as well as inorganic matter. The latent energy present in its organic fraction can be recovered for gainful utilisation through adoption of suitable Waste Processing and Treatment technologies. The recovery of energy from wastes also offers a few additional benefits as follows:The total quantity of waste gets reduced by nearly 60% to over 90%, depending upon the waste composition and the adopted technologyDemand for land, which is already scarce in cities, for landfilling is reducedThe cost of transportation of waste to far-away landfill sites also gets reduced proportionatelyNet reduction in environmental pollutionEnergy can be recovered from the organic fraction of waste (biodegradable as well as non-biodegradable) basically through two methods as follows:Thermo-chemical conversion: This process entails thermal de-composition of organic matter to produce either heat energy or fuel oil or gas;Bio-chemical conversion: This process is based on enzymatic

Automobile Shredder Residue(ASR) Recycling

2022-05-09Auto shredder residue (ASR), also referred to as auto shredder fluff, shedder light fraction (SLF), residues from shredding (RESH) or simply “auto fluff” of “fluff”, is the fraction of an shredded end-of-life vehicle (ELV). In the past, it was landfilled. Now, They can now be sorted and recycled thanks to AIShred's sorting and shredding technology. It can prevent this useful and valuable material from taking up the dwindling space in landfills and contribute to a cleaner, safer environment. How ASR Produced?A discarded car is first partially dismantled. All liquids (oils, antifreeze, fuel, etc.) are removed from it. Batteries, tires and catalytic converters are also removed and sent for further processing. Depending on demand, other good parts can be dismantled and sold for use as spare parts. On average, about 10% of the car's weight is pre-dismantled. In a shredder, a car body is shattered into pieces the size of a fist. 70-75% of the various metals from the body are sorted and sold to smelters and

Fuel Processing for RDF, TDF and SRF

2022-05-05Since the beginning of the 21st century, more and more waste has been generated. In order to cope with the threat to the environment caused by the increase in waste, people have begun to use waste as fuel that can be burned in boilers for power generation or heating. We divide the fuel from waste into RDF, TDF, SRF according to different components and processing method of the waste. RDF(Refuse-derived fuel) is a fuel produced by sorting and shredding combustible materials contained in municipal solid waste (MSW) and industrial waste. Compared to fossil fuels, RDF is more affordable, abundant, and environmentally friendly. SRF(Solid Recovered Fuel) is a fuel produced by drying, filtering, and shredding solid waste, It is usually produced to meet the standards in Europe. The EN 15359 document gives the specifications for classifying SRF. Unlike RDF, SRF is a more refined material that is slightly more efficient than RDF, though it takes a more advanced process to make the fuel. TDF(Tire-derived fuel) is a

In biomass power plants or thermal plants, which need to consume a large amount of fuel continuously, they buy large amounts of agricultural wastes from farms, such as corn, wheat, rice straw, sugarcane bagasse, palm husks, etc., which are used as fuels that can be burned in boilers. The fuel processing system is the necessary equipment to turn these biomass into qualified fuel, the shredder is the core equipment of the fuel supply system. In the biomass fuel supply system manufactured by AIShred, we recommend the use of a dual-shaft shearing shredder, which can shred the waste to a minimum of 5cm, maximum production capacity upto 60 tons per hour, high water content materials can be handed,which meets the requirements of most biomass power plants. AIShred can help you design a biomass power plant fuel processing system according to your boiler type, site layout and other technical requirements to ensure safe, stable and up-to-standard operation.

Every year, hundreds of billions of tons of organic biomass are formed on Earth - the waste products of living organisms. Biomass produces 10 times more energy than all the inhabitants of the Earth need today. Biomass ranks 5th in the list of renewable energy sources - after solar, wind, water and geothermal energy. Biomass sources are:fallen leaves and peat;wood and wood waste;human waste;industrial activity waste;special plants and cropsBiomass Processing MethodsThe conversion of biomass into fuel or thermal energy is carried out in five main ways:Incineration is the easiest and most popular way to obtain cheap energy from dry organic waste. During the incineration of waste, steam is generated in the boiler, the steam rotates the turbine, and that, in turn, moves the rotor of the generator that produces electricity. This method has a minus - the boiler becomes clogged with ash and soot, and production costs increase. Therefore, not all types of organic waste are used in direct combustion.Gasification is

Alternative Fuels Pre-processing Shredder

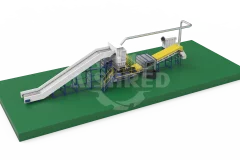

2022-04-08The GD Series double shaft shredder is designed to be versatile, making it suitable for pre-processing a wide range of solid alternative fuels. It can handle materials from municipal solid waste, industrial and commercial waste, to agricultural and forestry residues, and even automotive and truck tires. These materials are frequently used to produce alternative fuels for incinerators, chain grate furnaces, CFB boilers, and rotary kilns.The winning feature of this shredder is that it is a low speed machine.It consists of two shafts with opposite rotation, independent of each other. The cut takes place thanks to the action of the rotating blades on the fixed blades which are installed on a crosspiece placed between the two shafts. The rotating blades and fixed blades are interchangeable and resharpenable.The distance between them is also adjustable to always have a clean cut. The machine can be equipped with a screening grid that allows to obtain a product of defined dimensions, suitable for use as a

Municipal solid waste (MSW) is household, commercial, and / or institutional solid waste. They consist of everyday items such as paper, grass clippings, plastic bags, furniture, clothing, bottles, rubber, metals, food waste, paints and batteries. They are not only of domestic origin, but also commercial (offices, retail and wholesale, restaurants), institutional (libraries, schools, hospitals, prisons) and industrial (packaging and administration). Most of them are classified as not dangerous. As part of their solid waste management plan, almost all countries are promoting source reduction, recycling and composting to reduce landfill disposal. Several countries have also adopted specific measures for the disposal of certain materials: leaves, grass clippings, yard waste, office waste and computer paper, newsprint, cardboard and corrugated cardboard, glass, plastic, aluminum and steel containers are prohibited in disposal plants. Many plants burn municipal solid waste at high temperatures not only to reduce

Biomass Straw Shredder for your Disposal

2022-04-08The burning of crop straw is currently being banned by the state, with radio stations, banners and mobile publicity vans appearing in the streets and lanes every busy season. "A series of slogans such as "Burning straw, fines and detention" and "Straw burning is everyone's responsibility" have made straw something that everyone shouts at, but in fact it is not. The right place, the straw will be burned, not only the state support, and to solve the rural problems, that straw is an incomparable resource, that time and place is what - incineration power. However, the size of biomass straw is too large to directly enter the boiler for combustion. AIShred provides you with professional biomass combustion pre-treatment solutions, using it's independently developed and produced biomass double-shaft shear shredder, which uses two rotating shafts in opposite directions for shearing and tearing to shred the straw to the size required by the boiler, and the material of the equipment is made of imported alloy materials

Waste-to-Energy (WtE) plants treated around 420 million tons of waste per year worldwide1. Thanks to the production of energy through waste incineration, WtE plants allow materials to be recovered and recycled. decrease the amount of waste sent to landfills and reduce the proportion of fossil fuels used as a source of energy production.Waste to RDFWaste shredding plant processes overproduction, bulky waste fractions, large packaging and unsorted commercial waste by transforming them into waste-derived fuels (RDF) in various qualities. These fuels can be sent to waste incineration plants, cement plants, steel plants, etc., to obtain certain economic benefits.Waste to Fuel PelletBy pelletization we mean the process of transforming waste, generally into pellets, to make it usable for other applications. To be transformed into pellets, the waste must first be shredded, crushed or pulverized. The materials thus obtained are then processed in a rotary drum or disc pellet machine with the aid of a binding agent,

Solid Secondary Fuel (SSF) is a fuel obtained from the dry component (plastic, paper, textile fibres, etc.) of non-hazardous waste, whether urban or special, by means of special separation treatments from other non-combustible materials such as glass, metals and inert materials (UNI 15358). An important work direction of AIShred: energy from waste. AIShred is a leading supplier of shredding technologies and waste-to-fuel overall solution. It is able to provide customers with high quality installations for the storage, dosage, transport and mechanical treatment of a wide variety of materials, in order to obtain a product free of foreign bodies and impurities. In this way, municipal waste can be turn secondary solid fuels. AIShred also supplies high performance multi-stage shredding systems for the production of secondary solid fuel in cement factories. AIShred is able to produce tailor-made solutions for each individual application. AIShred is a leading provider of recycling and waste treatment technologies.

Polyethylene(PE) is a thermoplastic polymer of ethylene. It is an organic compound which is the most common plastic in the world. There are many types of polyethylene, which can be seen everywhere in our lives. The common ones are as followsLDPE(Low Density Polyethylene)HDPE(High Density Polyethylene)MDPE(Medium Density Polyethylene)LMDPE(Linear Medium Density Polyethylene)LLDPE(Linear Low Density Polyethylene)VLDPE(Very Low Density Polyethylene)ULDPE(Ultra Low Density Polyethylene)mLLDPE(Metallocene Linear Low Density Polyethylene)XLPE(Cross-linked Polyethylene)UHMWPE(Ultra High Molecular Weight Polyethylene)Thanks to its low cost and good chemical properties, PE materials are widely used in industry, commerce, construction and daily life. However, discarded PE products are difficult to degrade, causing huge damage to the environment. The good news is that we now know how to solve these problems. The first method is recycling. After the polyethylene waste is recycled, it is sorted and cleaned, shreded into

Particle Board, MDF(Medium Density Fiberboard) and Plywood are widely used in the retail sector, such as in shop fittings and furniture.Their widespread use as an alternative to solid wood reduces the deforestation. Although they have many differences, but the main ingredient of them are wood fiber. A large amount of particle board, MDF and plywood wastes are generated every year in the world, and the treatment of these wastes can turn them into materials for making recycled boards, or for energy utilization.AIShred Industrial Wood Shredder MachineParticle Board, MDF and Plywood are hard to process, a large number of disposals have high demands on stability and require a reliable device for the tough tasks. AIShred offers a wide range of industrial shredders for particle borad, MDF, plywood and other materials accroding the finally applications. For example, double shaft shredder for coarse shredding, single shaft shredder for fine shredding. AIShred also have mobile shredding plant that can work at jobsite

Industrial Shredder for Alternative Fuels

2022-04-06Waste is a stable and profitable energy source. Material that has been used and disposed of can be turned into energy-efficient fuel to replace or complement other sources of energy in various applications. Waste fuels, often referred to as “alternative fuels,” are generally produced from municipal solid waste and commercial and industrial waste. Common types of alternative fuels are refuse-derived fuel (RDF) and solid recovered fuel (SRF). There is enormous potential in alternative fuels. They eliminate waste and limit the purchase of black energy sources. Removing impurities and substances with low energy content allows higher-quality waste fuel to be produced. An efficient and properly designed production process increases the calorific value of the waste fuel and ensures that the fuel is optimal for the application. This has a considerable positive impact on production and finances. We manufacture industrial waste shredders and provide maintenance and professional services for companies producing or

Bioenergy is energy obtained by using biomass as a fuel, and is an alternative energy that can be used as a material of biological resources. Biomass used as an energy source is an organic matter that stores sunlight in the form of chemical energy, which uses wood, wood waste, straw, manure, sugar cane, and other by-products from various agricultural processes as fuel. Bio energy utilization refers to technologies such as chemical, biological, and combustion engineering that use biomass directly or in the form of liquid, gas, solid fuel, or electrical and thermal energy through bio-chemical and physical conversion processes. Industrial shredder is a necessary pretreatment equipment for large-scale utilization of bioenergy. It efficiently and quickly chops biomass materials into small sizes, which helps to improve the efficiency of subsequent processing. For example, in a biomass power plant, an automated industrial shredding system can continuously supply fuel and shred biomass into the required size, which

Green waste and biomass refers to wastes from animals and plants, which do not need to be wasted and can be converted into fuel or fertilizer. With AIShred's shredding systems, these wastes can be efficiently disposed of for biomass fuel, aerobic/anaerobic fermentation or other further processing requirements. As shown in the picture above, the waste from urban arbor pruning can be shredded into pieces using an industrial shredder and sent to biomass power plants for incineration and power generation. AIShred Twin-Shaft Shredder is a ideal machine to process green waste and biomass.Twin-Shaft ShredderThe twin shaft shredder have two rotating shafts, which allows them to process very hard and large materials. Due to the high strength of the knives and the hexagonal shaft system, they are able to shred hard and tough materials, such as cellulose and lignin. All shredders are supplied with an automatic load control system and shaft speed control with reverse rotation. When the load is exceeded, the system

The global demand for various paper products is increasing day by day, which is causing paper mills (and recycled paper mills) everywhere to operate at full capacity, while also generating a large amount of solid waste, including pulp waste, twisted rope, light residue, steel wires, etc. Landfills cause pollution, and now paper mills have new options, It can be made into bulk fuels or RDF pellets after shredding, separation and dring. AIShred Industrial Waste Shredding PlantAIShred industrial waste shredding plant is specially designed to handle difficult-to-handle industrial materials. With high torque, it can easily shred materials to the required size(