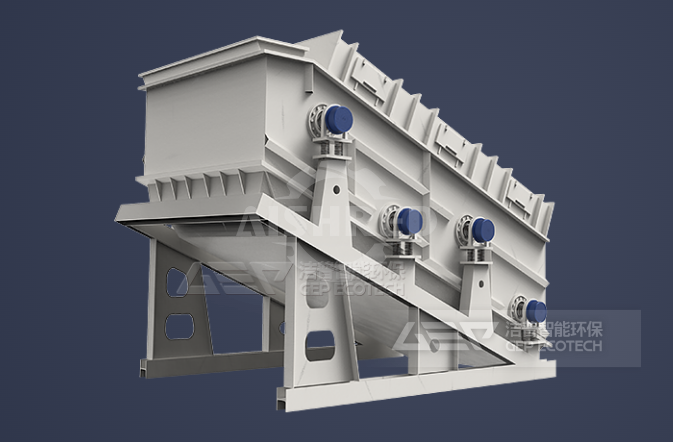

The flip flow and anti blocking screen technology, is an innovative technology in the field of screening. With its unique anti blocking mechanism and efficient screening performance, it has been widely used in various industries such as coal, mining, construction, and chemical. The following provides a detailed analysis of GEP ECOTECH's flip flow screen from the aspects of technical principles, application fields, and development trends.

Technical principle: in-depth analysis of flip flow and anti blocking technology

The core of the flip flow screen technology lies in the periodic flip flow motion of the screen, combined with high acceleration vibration, to achieve rapid loosening and layering of materials, thereby preventing screen hole blockage. The technical principles can be summarized as follows:

Varicose movement of elastic screen mesh

The screen mesh is made of high elasticity materials such as polyurethane, and driven by a vibrator, the screen mesh undergoes high frequency dilation and contraction at 800 times per minute.

During the process of screen mesh varicose, the sieve holes undergo periodic deformation: when the sieve mesh expands, the sieve holes become larger, allowing particles close to the sieve hole size to pass through; When shrinking, the sieve holes return to their original state to prevent particles from getting stuck.

High acceleration promotes material looseness

The vibrator generates a high acceleration, causing the material to move at high speed on the sieve surface. Fine particles quickly pass through the sieve holes, while large particles are thrown up to avoid accumulation.

This motion mode effectively solves the problem of clogged holes in damp and viscous materials (such as raw coal and mineral materials), significantly improving screening efficiency.

Block design and wear resistance optimization

The screen adopts a segmented design, and partial damage can be replaced separately to reduce maintenance costs.

Polyurethane material has excellent wear resistance and impact resistance, extending the service life of the screen mesh.

Applications: Efficient screening solutions for multiple industries

Flip flow screen with its excellent anti blocking performance and adaptability, has been widely used in the following fields:

Coal and Mining

Raw coal screening: Processing high moisture and viscous raw coal to achieve deep dry screening and improve the yield of clean coal.

Mineral classification: Accurately classify materials such as bauxite and coke to improve resource utilization efficiency.

Construction Industry

Soil particle analysis: used for soil particle size detection in foundation engineering to ensure project quality.

Concrete aggregate screening: Separate impurities from recycled aggregates to improve concrete performance.

Chemical and Pharmaceutical

Fine material screening: meets the requirements of high-purity and high-precision screening, such as the grading of pharmaceutical raw materials.

Anti blocking treatment: For viscous and easily clumped materials, ensure the continuity of the production process.

Metallurgy and Electric Power

Sticky lump ore processing: solves the problem of screening sticky lump ore under the blast furnace trough, ensuring stable feeding.

Coke screening: Improve the uniformity of coke particle size and optimize metallurgical processes.

GEP ECOTECH deeply explores the development trend of flip flow screen: innovation driven and green upgrading

- Structural innovation and reliability improvement: exploring new connection methods (such as non-rubber springs) to solve the problem of fatigue failure of traditional rubber springs and extend equipment life; Optimize dynamic design to reduce vibration noise and energy consumption.

- Integrated intelligent control system: Equipment is equipped with sensors to achieve integration with the Internet of Things, providing real-time optimization of vibration parameters and fault warning; Through data analysis, provide customized screening solutions to adapt to different material characteristics.

- Green manufacturing and environmental upgrading: promote environmentally friendly materials, develop energy-saving vibrators, and reduce equipment operating energy consumption.

- Customized services and scenario expansion: Provide customized screening and vibration parameters based on material characteristics such as viscosity and particle size; Expand into emerging fields such as new energy materials and food processing to meet diverse needs.

Why Choose GEP ECOTECH?

Customized Solutions: We offer tailored screening solutions based on your specific material characteristics and production requirements.

Comprehensive Support: From initial consultation to installation, maintenance, and spare parts, our global team ensures uninterrupted operation.

Quality Assurance: All products undergo rigorous testing to ensure they meet our high standards for performance and durability.

Contact us today to discuss your specific application needs and discover how our advanced screening solutions can optimize your operations. Request a personalized quotation or ask our technical team for a detailed solution tailored to your requirements!