Currently, the global resource utilization of waste tires is entering a period of rapid development. Every year, the number of scrapped tires is increasing, urging the tire recycling market to continuously optimize and upgrade to meet the rapidly growing demand for waste management. This also proves that there are huge business opportunities in the recycling industry of used tires.Against the backdrop of mechanical recycling of tires becoming the mainstream choice, data shows that the recycling price of rubber powder fluctuates between $200 and $280. In addition to explicit benefits, governments in multiple countries also have different subsidy policies for the disposal of waste tires, bringing hidden benefits to investors. Rubber powder can be used to manufacture recycled rubber, modified asphalt, as well as in the fields of construction, civil engineering, and industry. Compared to coarse rubber powder, fine rubber powder has fewer restrictions on its application range, and its selling price and profit are

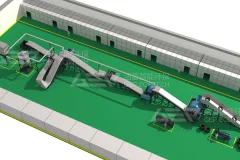

With the rapid accumulation of end-of-life tires, tire waste has become a global environmental concern. GEP ECOTECH provides a reliable and high-performance rubber granules production line, engineered to convert waste tires into valuable rubber granules and fine powder, supporting both environmental protection and circular resource utilization.Wide Material AdaptabilityThis production line is suitable for processing waste tires with a diameter of φ1200mm or smaller, including car tires, truck tires, and light commercial tires. It is ideal for tire recyclers looking to handle a wide range of input materials with varying structures and reinforcement levels.Core Equipment and Working ProcessThe system begins with a tire debeader to remove the tire bead wires (mainly for tires with a diameter from 800 to 1200mm), and then put the tires into a heavy-duty tire shredder, while those smaller tires can be directly shredded by the tire shredder. Alternatively, we can choose an integrated slicing and dicing machine, to

In the production process of RDF, improving the calorific value is the key to ensuring its energy efficiency and economic value. Since some domestic waste, construction waste and industrial solid waste have low calorific values, adding high calorific value materials has become an important strategy to optimize RDF performance. Waste tires have become the best choice to improve the calorific value of RDF.Why choose tiresWaste tires contain a lot of rubber and carbon black, and have excellent combustion performance:· High calorific value: The calorific value of tires can reach 30-35 MJ/kg, which is much higher than that of domestic waste (about 6-12 MJ/kg)· Stable combustion support: A small amount of addition can significantly improve the overall calorific value and combustion efficiency of RDF· Resource utilization: Achieve the reduction, harmlessness and high value of waste tires, and reduce environmental pollutionHow to add· Pretreatment: According to actual needs, use integrated slicing and dicing machine

In the process of waste tire recycling, the complete separation of rubber and steel wire directly impacts the purity of the output and the efficiency of downstream processing. As a leading solid waste treatment technology company, GEP ECOTECH has developed a high-performance tire steel wire separator to provide efficient, stable, and eco-friendly solutions for mid-stage tire processing. It has earned the trust of many recycling enterprises.DefinitionThe tire steel wire separator, also known as Tyre Rasper, is an essential piece of equipment in waste tire recycling lines. It is used to deeply separate embedded fine steel wires from mid-sized rubber granules (typically 50–80 mm in size) after initial shredding. This improves rubber purity and the overall value of recycled materials.Why It Is NecessaryWaste tires contain a large amount of embedded steel wires. If not properly separated, these wires can:Reduce the quality of rubber granules or powderCause wear or damage to granulators and milling machinesIncreas

Tire debeaders, also known as tire bead wire removers, play a crucial role in the waste tire recycling process. These machines are specifically designed to extract the thick steel wires embedded in the bead of large tires, such as those used on trucks, buses, and off-the-road (OTR) vehicles. This machine can be widely used in EOL (End-of-Life) tire dismantling, waste tire recycling, steel wire recovery, etc., serving as a core tire recycling plant. Why Tire Debeaders Are so Important? Tire debeaders are essential equipment for waste tire recycling. Traditional manual wire removal is inefficient and hazardous, while direct shredding contaminates rubber with steel wires, compromising recycled rubber quality and potentially damaging downstream equipment. The GEP ECOTECH Tire Debeaders can completely remove tire bead wires from whole tires in just 1-2 minutes, or even less time, achieving clean separation between steel and rubber. This not only protects downstream equipment like shredders and granulators from ex

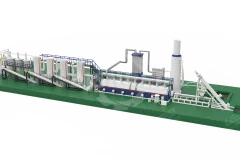

GEP ECOTECH offers a state-of-the-art continuous waste tire pyrolysis system designed to convert scrap tires into valuable products such as pyrolysis oil, carbon black, steel wire, and syngas, with near-zero emissions and continuous, automated operation. This technology is ideal for investors seeking sustainable and profitable solutions for waste rubber recycling.Key Process OverviewFeeding: Rubber shreds are fed into a sealed extruder and conveyed to the pyrolysis reactor.Pyrolysis Reaction: Occurs at 390–430°C under micro-negative pressure in an oxygen-deficient chamber.Oil-Gas Separation: Oil vapors are condensed into liquid fuel; non-condensable gas is purified.Fuel Recycling: Cleaned syngas is reused as a heating source for the pyrolysis reactor.Solid Separation: Steel and carbon black are magnetically and thermally separated.Emission Control: Flue gases are treated to meet environmental regulations.Closed-loop Cooling: Efficient water system ensures minimal water and energy use.Centralized Control:

Waste tires contain bead wires, which, if not removed, may cause increased wear and even damage to equipment such as tire shredders. The use of tire debeader can effectively reduce equipment wear and maintenance costs. At the same time, it can greatly improve the efficiency of waste tire processing, reduce environmental pollution, and increase resource recovery rate, making it an important equipment in the waste tire recycling industry, rubber regeneration, and environmental protection industry. The tire debeader, also known as tyre bead wire remover, tire bead wire puller, or bead extraction machine in some regions, is an essential piece of equipment in the waste tire recycling process. As one of the key tire recycling plants in the pre-treatment stage, it efficiently separates the steel bead wires from tires, preparing them for further processing such as shredding, granulation, or pyrolysis.Applicable Tire SizesThe tire debeader is usually suitable for waste tires with a diameter ranging from 800mm to

Currently, waste tire pyrolysis and oil refining equipment mainly comes in two types: batch and continuous. When selecting pyrolysis and oil refining equipment, companies often face the dilemma of choosing between batch and continuous equipment. Below, we will compare these two types of equipment in detail from key perspectives such as production efficiency, material requirements, environmental performance, automation level, and cost and return on investment, to help you make a more informed decision. 1. Production Efficiency Batch equipment operates in a batch processing mode, handling a batch of waste tires at a time. After each batch is completed, the equipment needs to be shut down for cooling, discharging products and residues, and then starting the next batch. Although this mode is simple to operate, the frequent start-stop cycles result in shorter effective operating times and lower production efficiency. Continuous equipment, on the other hand, enables 24-hour uninterrupted production. Raw materials

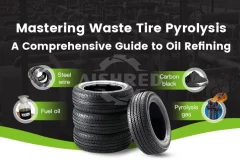

Discover the process of waste tire pyrolysis and oil refining. Learn how thermal cracking transforms tires into valuable resources like tire oil, carbon black, and pyrolysis gas. Explore different technologies, benefits, and applications for sustainable recycling solutions.

Tire Pyrolysis System

2025-01-13Tire pyrolysis systems offer a comprehensive and high-level recycling solution for end-of-life tires by using high temperatures in a low-oxygen environment to decompose rubber into valuable byproducts such as tire pyrolysis oil, pyrolysis gas, and carbon black. The system typically consists of a reactor (kiln), oil-gas condensation equipment, and a flue gas purification device. Pre-treatment systems may be required in some cases to process tires into suitable sizes.GEP ECOTECH offers two types of tire pyrolysis systems: batch systems and continuous systems. Batch systems are ideal for smaller-scale operations and applications requiring high flexibility, capable of processing whole tires directly. They offer lower initial investment costs and simpler operation. Continuous systems, on the other hand, are designed for large-scale, continuous production, achieving maximum conversion efficiency with pre-treated rubber powder. They offer higher throughput and automation but require a larger initial investment.GEP

Tire pyrolysis oil refining has become increasingly popular due to its simplicity and high profitability. Many tire recycling companies are adopting or exploring this technology as it not only generates valuable oil from waste tires but also reduces environmental impact. Its flexibility to integrate seamlessly with existing recycling lines makes it an efficient choice for production expansion. Additionally, the process helps lower dependency on fossil fuels by creating alternative energy sources, aligning with global sustainability goals.Price of Tire Pyrolysis Production LineWhen it comes to tire pyrolysis oil refining systems, the cost is a major concern for both newcomers and experienced recyclers. However, the price can vary significantly depending on the system's configuration and capacity. To help you better understand, let’s explore the different types of pyrolysis systems and their general price ranges.Batch-Type Pyrolysis SystemThe batch-type pyrolysis system is the go-to choice for most entry-level

What Would a Tire Granulating Line Be Like?

2024-09-29Recently, a Latin America customer inquired about a 5-ton per hour tire granulation line project, of which 90% are car tires, and the rest are truck tires, tractor tires, bus tires, etc., but the diameter does not exceed 1200mm. The customer's requirements for the discharge particle size are relatively wide, and they have the following applications:1. Around 50x50mm, to be used as a substitute fuel for cement kilns and generates energy through combustion2.<1mm, to be used as rubber powder for fine sand and mortar for construction, or for sewage treatment3. from 2 to 5mm, to be used as a medium: coarse sand for reinforced concrete, paving, and asphalt productionThe client is a turnkey engineering company that provides comprehensive solutions with financial, environmental, and operational goals for various fields such as industry, shopping centers, hospitals, and commercial buildings. After preliminary communication, it has been determined that the project is currently in the feasibility study stage, and our

Four-Shaft Shredder for Tyre Crushing

2024-09-10When it comes to shredding tires, there are various equipment options available, such as single-shaft or dual-shaft shredders. However, using GEP ECOTECH's four-shaft shredder offers a significant advantage by shredding tires to a size of less than 40mm in a single pass. Combined with granulators and steel wire separators, this solution can produce clean rubber granules. Get a comprehensive look at GEP ECOTECH's tire recycling solutions

How to Reuse Waste Tires?

2024-03-27There are several ways to reuse waste tires, also known as scrap tires, in an environmentally friendly and economically beneficial manner.Here are some common methods:1. Tire Recycling Plants: These facilities specialize in shredding tires into their original components such as rubber, steel, and fiber. The rubber can be ground into small granulates or powders, which is used in various applications including playground surfaces, athletic tracks, and rubberized asphalt for roads.2. Tire-Derived Fuel (TDF):Tires can be shredded into smaller pieces and used as a fuel source in industries like cement manufacturing and pulp and paper mills. TDF serves as an alternative fuel, reducing the consumption of fossil fuels and diverting tires from landfills.3. Tire Pyrolysis:Pyrolysis is a process that involves heating tires in the absence of oxygen to break them down into oil, gas, and carbon black. The resulting products can be used as fuel, chemical feedstock, or as filler material in various industrial applications.4

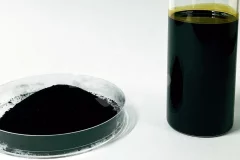

Tyre Rubber Powder Uses

2023-11-28Tyre rubber powder, derived from the recycling of tires, specifies a size between 0.1 and 1 mm,is completely clean, free of any iron or fiber, finds various applications across industries due to its versatile nature and beneficial properties. Some common uses of tyre rubber powder1. Rubber Products Manufacturing:Rubber Industry: The powder is utilized as a raw material in manufacturing new rubber products, including:Tire Manufacturing: Incorporation into new tire compounds or tread patterns.Rubberized Asphalt: Blending with asphalt for road construction, enhancing durability and skid resistance.Rubber Mats and Flooring: Used for making rubber mats, flooring tiles, or other similar products.2. Construction and Building Materials:Construction Industry: Tyre rubber powder is incorporated into construction materials due to its shock-absorbing and insulating properties, used in:Rubberized Concrete: Enhancing concrete properties like flexibility and vibration damping in construction.Playground Surfaces: Mixes for

Waste tire recycling machine for rubber powder, also known as rubber powder production line, is designed to convert waste tires into rubber powder or granules for various applications. These machines typically go through several stages to process tires into usable rubber powder. Here are some key components and steps involved in the process:Rubber Powder Production Line1. Tire Shredding:Tire Cutter/Shredder: Used to cut or shred tires into smaller pieces or strips, increasing the surface area for subsequent processing.2. Granulation or Grinding:Rubber Crusher/Grinder: Further reduces the shredded tires into granules or fine rubber powder.3. Magnetic Separation:Magnetic Separator: Removes steel wires and other metallic components from the rubber material obtained from the grinding process.4. Fiber Separation (Optional):Fiber Separator: Separates and removes fiber materials from the rubber powder, depending on the desired purity of the final product.5. Fine Powder Processing (Optional):Fine Grinding/Milling

SBR Granules Production Plant

2023-08-01"SBR" is an acronym for "Styrene-Butadiene Rubber," a synthetic rubber known for its versatility and numerous applications. When enhanced with additives, SBR exhibits exceptional resistance to abrasion and aging, making it a preferred choice in various industries. The popularity of SBR granules has grown significantly due to their diverse uses in engineering and construction projects, as well as their wide application in the production of rubber products, road repair, sports surfaces, tracks, rubber flooring, and more. SBR granules are derived from waste tires or other rubber materials through a straightforward and efficient manufacturing process. The key stages of production encompass shredding, steel wire separation, granulation, and fiber separation. GEP ECOTECH boasts extensive expertise in assisting customers with the design, manufacturing, and construction of rubber granule production lines. Our solutions are meticulously tailored to suit specific requirements, including raw materials, site conditions

Waste Tyre Recycling Process

2022-05-05Thanks to the development of technology and industry, as well as the standard of living of the population, the number of cars is increasing every year, and with it the production of car tires is also growing. Since their service life does not exceed 5 seasons on average, the problem of the tire recycling process is acute all over the world. Modern tires are a source of valuable materiales and include:Rubber - synthetic or natural, various resins and carbon black, which together form a complex structured rubber shell.Metal elements such as bead rings and reinforcement wire.Textile reinforcement threads made of synthetic fabrics.The remaining components, for example, glue. Due to the development of technology and the improvement of downstream industries, tire recycling has become profitable, and many companies have shown interest in it. Here I‘d like to introduce the process of tire recycling to solve the doubts of many beginners:Scrap Tyres are transported via mechanical trolley into the Processing Warehouse

Effective answers to the problem of tire recycling to obtain secondary raw material that can be reused in various fields. Since the beginning of its business, AIShred has been offering careful and effective solutions to the problem of tire recycling, making it possible to obtain - starting from the end-of-life tire - secondary raw material in different grain sizes, with the simultaneous separation of steel and textile fiber.Tires Recycling Processing The first phase of the process involves the extraction of the steel ring present in the tires, which is then stored through different stages of magnetic separation. Subsequently the material is shredded and reduced in size until it reaches a uniform granulometry from 0 to 4 mm. The plant is equipped with a cleaning system articulated in several phases which guarantees the complete separation of the textile fiber, so as to obtain a 99% pure granulated product. Furthermore, an advanced suction system, supported by filters and fire-fighting measures, allows the

Waste Tire Processing

2022-03-03The management of end-of-life tires has always been an important issue in environmental conservation. Billions of scrap tires are generated globally every year. These accumulated waste not only take up a lot of space but can also cause fires and release harmful chemicals, posing potential threats to the environment and health. Effective recycling of scrap tires is receiving increasing attention. Fortunately, innovative developments are taking place in this area. There are now more mature and environmentally friendly treatment methods for end-of-life tires, which can be converted into derived fuels, recycled rubber, fuel oil, or other useful substances.GEP ECOTECH boasts extensive expertise in tire recycling, offering the capability to design and implement complete production lines tailored to the specific needs. Our versatile range of equipment combinations enables us to meet diverse tire and other rubber products recycling needs—be it recycling rubber chips, granules, powder, or for pyrolysis—at different