Tire shredders, also known as tire crushers or tire granulators, are used to reduce tires into smaller pieces, often as part of recycling processes. There are different types of tire shredders, each suited for different stages of processing used tires. Here are some common categories:Primary Shredders: These machines are designed to take whole tires and shred them into large rubber chunks. They typically feature sturdy blades or knives capable of handling tires of all sizes, including those from trucks or construction equipment.Secondary Shredders: After tires have been processed by a primary shredder, secondary shredders further reduce the size of the fragments into smaller pieces, usually a few centimeters in size.Granulators: Granulators are used to produce uniform-sized rubber granules. These machines often come equipped with screening systems to control the size of the finished product.Micro-Granule Shredders: They produce very small pieces of rubber, called micro-granules, which can be used in the

How to Reuse Waste Tires?

2024-03-27There are several ways to reuse waste tires, also known as scrap tires, in an environmentally friendly and economically beneficial manner.Here are some common methods:1. Tire Recycling Plants: These facilities specialize in shredding tires into their original components such as rubber, steel, and fiber. The rubber can be ground into small granulates or powders, which is used in various applications including playground surfaces, athletic tracks, and rubberized asphalt for roads.2. Tire-Derived Fuel (TDF):Tires can be shredded into smaller pieces and used as a fuel source in industries like cement manufacturing and pulp and paper mills. TDF serves as an alternative fuel, reducing the consumption of fossil fuels and diverting tires from landfills.3. Tire Pyrolysis:Pyrolysis is a process that involves heating tires in the absence of oxygen to break them down into oil, gas, and carbon black. The resulting products can be used as fuel, chemical feedstock, or as filler material in various industrial applications.4

The Essential Guide to Tire Shredding

2024-01-31The disposal of used tires represents a significant environmental challenge worldwide. Tire shredding is a fundamental solution to this problem, transforming end-of-life tires into valuable materials for various industries. This process not only helps in managing waste efficiently but also contributes to reducing the ecological footprint of tire disposal.Understanding Tire ShreddingTire shredding is the process of breaking down used tires into smaller, manageable pieces. These pieces can then be repurposed for a variety of applications, ranging from rubber mulch for landscaping to crumb rubber for athletic tracks and fields. The process involves several stages, each designed to reduce tires to a specific size and remove contaminants such as metal wires and synthetic fibers.The Tire Shredding ProcessCollection and Pre-processing: The initial step involves collecting the used tires and preparing them for shredding. This may include inspecting tires for any reusable qualities or removing rims and other non-

Waste tire recycling machine for rubber powder, also known as rubber powder production line, is designed to convert waste tires into rubber powder or granules for various applications. These machines typically go through several stages to process tires into usable rubber powder. Here are some key components and steps involved in the process:Rubber Powder Production Line1. Tire Shredding:Tire Cutter/Shredder: Used to cut or shred tires into smaller pieces or strips, increasing the surface area for subsequent processing.2. Granulation or Grinding:Rubber Crusher/Grinder: Further reduces the shredded tires into granules or fine rubber powder.3. Magnetic Separation:Magnetic Separator: Removes steel wires and other metallic components from the rubber material obtained from the grinding process.4. Fiber Separation (Optional):Fiber Separator: Separates and removes fiber materials from the rubber powder, depending on the desired purity of the final product.5. Fine Powder Processing (Optional):Fine Grinding/Milling

Optimizing the Use of a Double-Shaft Shredder for Processing Waste Tires into Rubber Powder

2023-11-18Introduction:The disposal and recycling of waste tires have become crucial environmental concerns worldwide. One effective approach is the utilization of a double-shaft shredder to process waste tires and convert them into rubber powder. This article aims to discuss the optimization of the double-shaft shredder’s operation for the efficient production of high-quality rubber powder.Selection of Shredder Parameters:To achieve optimal results, several key parameters of the double-shaft shredder should be considered:Shredder Speed: Adjusting the speed of the shredder blades ensures the proper size reduction without excessive energy consumption.Blade Configuration: Choosing the appropriate blade design and spacing enhances the shredding efficiency and minimizes the generation of excess heat.Shredder Capacity: Ensuring the shredder’s capacity matches the throughput requirements guarantees smooth and continuous tire processing.Tire Preparation:Effective tire preparation is essential for maximizing the shredder’s

SBR Granules Production Plant

2023-08-01"SBR" is an acronym for "Styrene-Butadiene Rubber," a synthetic rubber known for its versatility and numerous applications. When enhanced with additives, SBR exhibits exceptional resistance to abrasion and aging, making it a preferred choice in various industries. The popularity of SBR granules has grown significantly due to their diverse uses in engineering and construction projects, as well as their wide application in the production of rubber products, road repair, sports surfaces, tracks, rubber flooring, and more. SBR granules are derived from waste tires or other rubber materials through a straightforward and efficient manufacturing process. The key stages of production encompass shredding, steel wire separation, granulation, and fiber separation. GEP ECOTECH boasts extensive expertise in assisting customers with the design, manufacturing, and construction of rubber granule production lines. Our solutions are meticulously tailored to suit specific requirements, including raw materials, site conditions

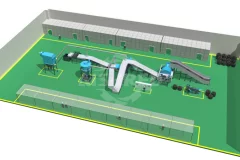

The increasing number of cars has resulted in a rise of scrapped cars. Several cities are now constructing industrial parks dedicated to dismantling and recycling these vehicles. While scrapped cars may seem useless, there are still many materials that can be recycled after dismantling. However, the tires of these scrapped cars have become a major problem. Stacking them in a centralized location not only occupies land but also increases the risk of fire, which negatively affects the environment. Fortunately, tires have some recycling value. As such, there is an urgent need for a production line that can turn waste tires into a valuable resource in the market. GEP ECOTECH is a professional supplier of solid waste solutions and equipment. They are able to independently design, develop, and manufacture a waste tire resource disposal production line that is tailored to the characteristics of waste tires and can meet various project disposal requirements. One example is the process of waste tire granulation:

When choosing a tire shredder, you should not only focus on the price, but also on the quality of the equipment. Consider the output, displacement, energy consumption, and choose a more suitable tire shredder equipment from the many tire shredder brands. What factors need to be considered when selecting a tire shredder?The characteristics of the material to be disposed ofWhen choosing a tire shredder, the selection should be based on the nature of the actual material to be processed. Different models of tire shredder equipment have different production capacities and can handle different materials. These differences have also become the criteria for distinguishing tire shredder equipment models. For example, to deal with large truck tires, choose a large tire shredder equipment. Equipment CapacityDifferent types of tire shredders have different unit processing capacities, and different tire shredder equipment consumes different amounts of energy in the process, so the operating costs are different. It is

The Recycling of Waste Tires

2023-02-09With the rapid development of the automobile industry and the increase of cars, the number of scrap tires produced each year is also increasing. According to statistics, the world is expected to produce a total of about 2.35 billion tires in 2021, and the number is increasing year by year, causing serious harm to the environment. And scrap tires are treasures everywhere, and can be recycled after treatment, so the treatment of scrap tires is not only environmentally friendly but also has huge economic benefits. There are three main directions of reusing waste tires:Waste tire cement kiln co-disposal: With the continuous increase of coal price and the implementation of double carbon policy, cement enterprises start to layout alternative fuel projects for waste tires, which is a very good high calorific value fuel that can save cost and reduce carbon emission.Thermal cracking of waste tires: The steel wire, carbon black, fuel oil and combustible gas after thermal cracking of waste tires can be obtained. These

Waste Tyre Recycling and Disposal Process

2023-02-07As an essential material in people's daily lives, waste tyres are increasingly becoming a disposal problem with the development of the automotive industry. The tyres themselves are highly utilisableThe following are the two most common tyre recycling processes.Pyrolysis: Pyrolysis is one of the most thorough methods of treating automotive waste rubber. Cracking treatment has no pollutant emissions, and can also recover fuel oil and carbon black, which is conducive to environmental protection and resource utilization and has high economic value, and is considered one of the best ways to treat waste tyres at present.Made into rubber powder/particles/blocks: waste tyres are made into rubber powder by normal temperature crushing method, normal temperature chemical method, etc. Rubber powder is widely used in sports plastic sports field, playground, rubber floor tile, waterproofing membrane, waterproof coating, highway modified asphalt, rubber products and other fields. In terms of making rubber powder, we

Our environment is facing challenges, hundreds of millions of end-of-life tires are encroaching on our space, polluting soil and groundwater, high temperatures can cause them to burn, and harmful smoke is polluting the atmosphere. Fortunately, we already know how to recycle this waste. Convert them to gold through material and energy recovery. Material RecyclingDue to the resistant rubber material, the material recycling of used tires is very expensive. The industry has high demands on recycled rubber; it must correspond exactly to the respective requirements. In material recycling, used tires are shredded in shredder and granulate plants and processed into powdered rubber or granules. The products obtained from material recycling can be reused, for example, for artificial turf, asphalt or sports fields or sealing materials. So that old tires can be separated into their three main components rubber, textile fibers and metal, the old tires must be crushed to a particle size of five millimetres. This is done

Management of ELTs (End-of-Life Tires) has become a global challenge and the correct disposal of this type of waste is becoming more important every year. AIShred has designed and produced a complete system for processing scrap tires that meets the various new requirements for the correct disposal of this type of waste. The tire shredding plants developed by AIShred are systems with zero environmental impact, allowing to obtain a clean product that can be used in many contexts as a new raw material. The Shredder GDT12 is one of the latest tire recycling systems developed by AIShred to meet specific needs without losing sight of productivity, which for economically sustainable processing must never fall below 5 tons per hour . The new Shredder GDT12 is equipped with special “clean-cut knives” to deal with the problem of frayed steel wire contained in the tyres. The Shredder GDT12 was developed with special consideration of the operating costs: the low speed and the high torque guarantee maximum performance

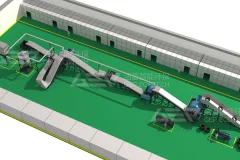

The waste tire resource recovery and reuse project can centrally dispose the waste tires, reduce pollution, and promote the high value-added utilization of waste tire resources. Its production, processing and reuse has far-reaching social significance and economic benefits, which can meet the market demand both at home and abroad. Recently, a customer in Kuwait purchased a complete set of waste tire disposal production line equipment from our company for rubber milling to make a rubber runway. This set of equipment mainly uses a steel wire drawing machine to remove the thick steel wire in the tires, and then the metal chain conveyor will transport the drawn tire to the tire crusher. The capillary steel wires will be removed from the broken waste tires through the steel wire separator, and use a separator to separate the steel wires. The removed steel wires can be used as a part of the profit source. The treated tires can be recycled as required. The whole production line is equipped with a pulse type dust

Scrap Tires to TDF with AIShred Shredders

2022-05-26Waste tires have great value and can turn them into alternative fuels used in cement kilns, power plants, steel mills, called TDF(Tire Derived Fuel), which reduces threats from unlawful stockpiling, while also creating economic profits. How is TDF produced?In simple terms, processing of discarded scrap tires into TDF consists of three main steps: shredding, screening and metal removal. The level of each is determined by the end user's needs and specifications (i.e., size of shreds and amount of metal removed). For shredding of scrap tires, equipment for tire processing generally comes in two types - slow speed and high-speed shredder. Slow speed shredder or rotary shear shredder is used to produce the larger chip sizes suitable for applications such as cement kilns, shearing the tire into 2 to 5-inch size shreds and liberating between 2 and 10 percent of the bead wire contained within the tire. The high speed single shaft shredder contains a rotor equipped with knives that shred the tire until they are of

Conventional fuels like hard coal and lignite that are commonly used fuels in cement production have high specific CO2 emission values (Hard coal: ~95 kg CO2/GJ; Lignite: ~98 kg CO2/GJ). Consequently, substituting these with other fuels having lower specific emssion values (e.g. fuel oil or natural gas) or with other sources that can satisfy the thermal demand of the processes is an effective way of reducing CO2 emissons. Principally, in cement kilns conventional fossil fuels can be substituted up to 100% by alternative fuels. Nevertheless, there are certain technical limitations like the calorific value, the moisture content, and the content of side products like trace elements or chlorine. The calorific value of most organic material is comparatively low (10 – 18 GJ/t). For the main firing of the cement kiln an average calorific value of at least 20-22 GJ/t is required, meaning that high calorific alternative fuels are mostly used in the main firing. Waste tyres can be used as a fuel in cement kilns. Waste

Waste Tyre Recycling Process

2022-05-05Thanks to the development of technology and industry, as well as the standard of living of the population, the number of cars is increasing every year, and with it the production of car tires is also growing. Since their service life does not exceed 5 seasons on average, the problem of the tire recycling process is acute all over the world. Modern tires are a source of valuable materiales and include:Rubber - synthetic or natural, various resins and carbon black, which together form a complex structured rubber shell.Metal elements such as bead rings and reinforcement wire.Textile reinforcement threads made of synthetic fabrics.The remaining components, for example, glue. Due to the development of technology and the improvement of downstream industries, tire recycling has become profitable, and many companies have shown interest in it. Here I‘d like to introduce the process of tire recycling to solve the doubts of many beginners:Scrap Tyres are transported via mechanical trolley into the Processing Warehouse

Rubber Powder Tyre Shredding Machine

2022-04-21Rubber powder is produced by fine grinding automobile tires without the formation of elevated temperature, it completely retains the properties inherent in the original material (ductility, elongation, modulus of elasticity, etc.). The average particle size is about 150 µm. In production of rubber powder, crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed. Rubber powder is applied in:production of thermoplastics, rubber products, production of composite roofing materials;as a modifying additive in the production of various kinds of mastics;as a key material of asphalt-concrete mixtures;as an adsorbent for petroleum products.How to Produce Rubber PowderTire recycling is a very complex process and a range of equipment is used. Whole tires are first shred into small pieces, then ground into granules, and finally produced into rubber powder. In this process, tire shredders, granulators and pulverizers will be used, and auxiliary machinery includes wire separators,

Tyre Recycling Shredder With Sieve for Sale

2022-04-13For small and medium-sized businesses that want to produce rubber granules or rubber powder (with an output of less than 50 tons per hour), we recommend the AIShred dual-shaft tire shredder, which integrates tire shredding and screening, with advantagesa of small footprint and long-term reliability. It is used as the main shredder for many new tire disposal businesses or expansion of old businesses. As shown in the picture above, this is a tire shredder with a sieve. It can process the entire tire. The function of the screen is to bring the tire fragments that do not meet the size requirements from the bottom into the top feed port for repeated shredding. , until it is discharged from the bottom after meeting the requirements. The video below shows the whole process intuitively: AIShred offers various technical routes of tire pretreatment systems, which are used to produce rubber pellets and rubber flour or tire-derived fuels. Read more:Waste Tire Shredding for Recycling & Tire Derived Fuel TDFAlternative

Effective answers to the problem of tire recycling to obtain secondary raw material that can be reused in various fields. Since the beginning of its business, AIShred has been offering careful and effective solutions to the problem of tire recycling, making it possible to obtain - starting from the end-of-life tire - secondary raw material in different grain sizes, with the simultaneous separation of steel and textile fiber.Tires Recycling Processing The first phase of the process involves the extraction of the steel ring present in the tires, which is then stored through different stages of magnetic separation. Subsequently the material is shredded and reduced in size until it reaches a uniform granulometry from 0 to 4 mm. The plant is equipped with a cleaning system articulated in several phases which guarantees the complete separation of the textile fiber, so as to obtain a 99% pure granulated product. Furthermore, an advanced suction system, supported by filters and fire-fighting measures, allows the

AIShred, New Industrial Shredder for Tires

2022-04-08AIShred is completing the design of a new industrial shredder specific for the treatment of waste tires. In terms of waste tire management, AIShred confirms that it is always attentive to the increasingly demanding demands of the market. With the aim of aligning with the terms of quality of the shredded tire, AIShred is completing the design of a new shredder capable of:Increase productivityEliminate the protruding steel wiresImprove the control of the output sizeDrastically reduce maintenance costsSignificantly limit electricity consumptionAIShred expects the first machine to be ready by May, it will be installed at one of the company's customers in Thailand with whom there is already a supply agreement. The company's expectations on the success of this new project are very high with the aim of placing 10 machines in the second half of 2022. However, the AIShred research department is also active in the development of complete and automated lines for the treatment of tires, with the aim of raising standards

Waste Tire Processing

2022-03-03Waste tires have a huge recycling value and GEP ECOTECH can offer different stages of waste tire shredding and recycling systems designed to increase resource efficiency and reduce space occupation and pollution. GEP ECOTECH has many years of hands-on project experience and can help customers design a tire recycling line that best meets their disposal requirements, reducing risk and costs and increasing profitability. GEP ECOTECH's tire shredding and recycling systems are available in a wide range of flexible combinations. Whether it is for wire separation, the production of rubber blocks, rubber granules, rubber powder or cracking, customers can always achieve their recycling goals thanks to GEP ECOTECH's strong technical capabilities and extensive practical experience. GEP ECOTECH has developed twin shaft shredders, steel wire separators, granulators, rubber breakers, fibre separators, mills, etc., specially optimized for tire recycling applications, which offer outstanding performance in terms of efficienc