Over the past decades, the use of agricultural films has continued to increase and shows a long-term upward trend. Growing demand for food and animal feed, shrinking arable land resources, rising requirements for soil protection, and the cost efficiency of plastic films have made agricultural film an indispensable input in modern agricultural production.At the same time, the widespread use of agricultural films has resulted in a rapidly growing volume of post-consumer film waste. With limited practical alternatives available, efficient recycling has become a critical pathway toward sustainable agricultural development. In this process, reducing lightweight, flexible, and highly tangled agricultural films into a uniform and controllable particle size is a decisive first step.GEP ECOTECH provides dedicated shredding and recycling solutions engineered specifically for post-consumer agricultural films. Built on extensive experience in solid waste treatment and plastics recycling, GEP ECOTECH agricultural film

Agricultural film, a crucial tool for increasing yield and preserving moisture in modern farming, brings economic benefits while also creating a growing "white pollution" crisis due to its non-biodegradable nature. Broken residual film entangled in soil hinders water and fertilizer penetration, affects crop root growth, and damages soil structure, directly threatening food security and ecological health. Therefore, promoting the scientific recycling and resource utilization of waste agricultural film has become a key task for rural revitalization and ecological civilization.Recycling Waste Agricultural Film: Unlocking Triple Value—Economic, Social, and EcologicalRecycling waste agricultural film is a meaningful endeavor:Significant Economic Value: The main component of waste agricultural film is polyethylene (PE), a tradable renewable resource. Through efficient sorting and purification, it can be transformed into high-value recycled raw materials or high-calorific-value fuel, generating direct economic

As an important helper in agricultural production, plastic film can effectively increase soil temperature, maintain soil moisture, inhibit weed growth, and create favorable conditions for crop growth. However, the main raw material for traditional agricultural film is polyethylene, which is difficult to degrade in natural environments and has become the main source of "white pollution" in farmland. Residual plastic film can damage soil structure, affect crop root growth, reduce crop yield and quality, and even cause diseases when ingested by livestock.At present, there are mainly two directions for agricultural film recycling: harmless treatment and resource utilization. Harmless treatment refers to the safe incineration or landfill of waste plastic film with low utilization value to avoid environmental pollution. Resource utilization processing can process recycled plastic film into recycled plastic pellets, which can be used to manufacture new plastic products such as garbage bags, shopping bags, and

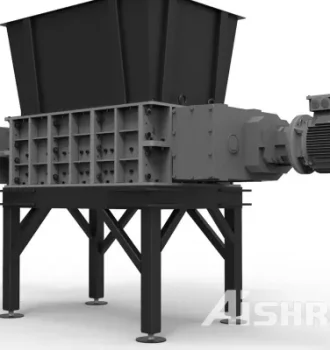

In today's plastic recycling industry, especially when dealing with Low-Density Polyethylene (LDPE) film scrap, the right shredding equipment determines not just efficiency but also profitability. LDPE films are notoriously difficult to process—thin, flexible, and often contaminated—making them a challenge for recyclers worldwide. A high-performance shredder breaks down bulky film waste into manageable, uniform pieces, ensuring smooth feeding for subsequent washing, granulating, and pelletizing. This first step is critical to transforming problematic plastic waste into a valuable secondary resource.To meet different recycling needs, a variety of shredding solutions are available. Single-shaft shredders deliver cost-effective size reduction, while dual-shaft models provide higher throughput and stronger cutting power. For demanding operations, quad-shaft shredders offer unmatched precision and reliability, minimizing downtime and maximizing recovery rates. By choosing the right machine, recyclers can cut

In the realm of plastic recycling and waste management, the constant advancement of shredding technology plays a pivotal role in maximizing efficiency and sustainability. One remarkable innovation in this field is the new upgraded single shaft shredder designed specifically for processing PE (polyethylene) film waste. This advanced equipment represents a significant step forward in improving the recycling process for PE film materials. In this article, we will delve into the features, benefits, and applications of this new upgraded single shaft shredder. Features of the New Upgraded Single Shaft ShredderEnhanced Cutting Mechanism: The new upgraded single shaft shredder is equipped with an enhanced cutting mechanism that efficiently shreds PE film into smaller particles. The precision-engineered blades are designed to achieve consistent and uniform results.Variable Speed Control: This shredder comes with variable speed control, allowing operators to adjust the shredding speed based on the specific

New Breakthrough in Waste Plastic Packaging Film Treatment: Waste Derived Fuel Technology

2023-08-17With the development of the economy and the rapid rise of the packaging industry, packaging waste is also increasing in large quantities, if not dealt with in a timely manner, will seriously pollute the environment, and over time the formation of a vicious and ungovernable trend. At present, the recycling and reuse of packaging waste has become an urgent task of environmental protection in all countries, but also the primary measures to combat global environmental pollution. Especially plastic packaging film, with easy aging, easy to break, short life cycle characteristics, if not handled in a proper way, the environment and the ecosystem will produce great harm. In addition, plastic film and other plastic products to petroleum as the main raw material, with the global consumption and depletion of petroleum resources, including waste plastic packaging film, including the recycling of waste plastics has also become a hot spot for people to study. A large amount of plastic packaging films are discarded

Agricultural film, also known as thin film plastic, including plastic film, is mainly used to cover farmland, improving soil temperature, maintaining soil moisture, promoting seed germination and rapid seedling growth, and inhibiting weed growth. The main component of agricultural film is non degradable polyethylene, so waste agricultural film can cause certain pollution to soil and water sources, and its recycling is very necessary. The methods for waste agricultural film recycling include:Compression landfill: Waste agricultural film is compressed and sent to a landfill site, which is commonly used but not advocated.Thermal energy utilization: During the incineration process of discarded agricultural film, a large amount of thermal energy is released for heating or power generation, which poses a certain environmental pollution risk.Artistic creation: Create artwork or daily necessities through creative design.Recycling: Agricultural film is processed into recycled plastic particles through drying,