Recycling of PV panels is crucial for resource reuse and environmental protection. End-of-life solar panels contain recyclable materials such as glass, aluminum, and silicon. Improper disposal not only wastes resources but may also cause environmental pollution. Efficient recycling enables the recovery of valuable materials, reduces carbon emissions, and promotes the sustainable development of the renewable energy industry.

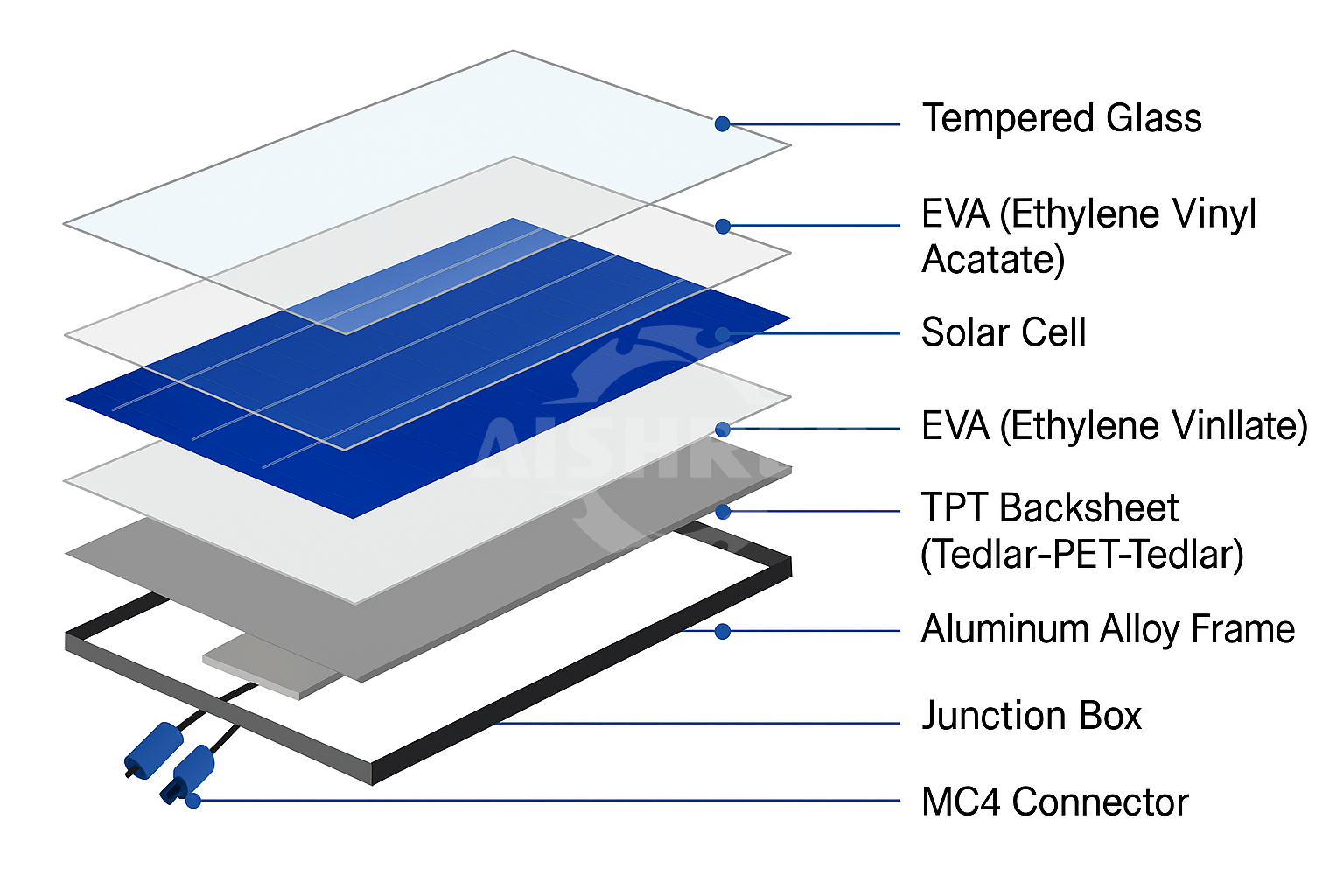

To better recycle waste PV panels, let's first look at what materials make up a solar panel:

- Tempered Glass: Protects against impact and weather.

- EVA Encapsulation: Seals and insulates the solar cells.

- Solar Cells: Convert sunlight into electricity.

- Conductive Copper Ribbon: Connects the cells electrically.

- TPT Backsheet: Insulates and protects the rear side.

- Aluminum Frame: Provides structure and mounting support.

- Junction Box (MC4): Ensures safe electrical output.

Steps in PV Panel Recycling

Recycling PV panels generally involves four main steps:

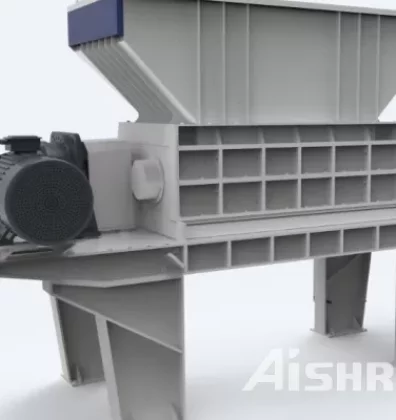

Step 1 Mechanical Dismantling (Physical Recovery) – Removal of the aluminum frame, junction box, and other outer components.

Step 2 Thermal and Chemical Treatment – Heating or chemical soaking to loosen bonding layers and separate encapsulated materials.

Step 3 Shredding – Using a shredder to break pre-treated solar cells into small fragments.

Step 4 Material Separation – Recovering valuable elements like glass, silicon, copper, and silver through magnetic, eddy current, or gravity separation.

Why Shredding (Step 3) Is the Most Important?

Among the above foure steps, shredding is a the most important step in PV panel recycling because it enables the safe and efficient breakdown of complex, layered structures. Solar panels are composed of tightly bonded materials—glass, aluminum frames, silicon cells, and plastic encapsulants—which must be separated for effective resource recovery. A high-performance shredder, such as a double-shaft shredder, reduces the panels into manageable pieces, exposing internal components and facilitating downstream processes like sorting, separation, and purification. Without shredding, valuable materials remain trapped, and recycling efficiency drops significantly. It's the foundation of a cost-effective, scalable, and sustainable recycling system.

Advantages of GEP ECOTECH's Double-Shaft Shredder for PV Panels

GEP ECOTECH's Double-Shaft Shredder is specially engineered for the safe and efficient disposal of end-of-life photovoltaic (PV) panels. With high-torque, low-speed cutting technology, it can effectively shred the composite structure of solar panels—including glass, aluminum frames, EVA film, and silicon layers—without generating excessive dust or damaging valuable components. The machine can be integrated into automated PV recycling lines, helping recyclers recover materials like aluminum, glass, and rare metals while supporting environmental sustainability. It has the following features:

- Monoblock Knife Box:One-piece machining and heat treatment ensure high structural strength, no deformation during long-term heavy-duty operation, ideal for shredding complex PV panel layers.

- Imported Alloy Blades:High toughness and wear resistance make them suitable for cutting through glass, metals, and polymers. Blades are repairable and reusable, reducing operational costs.

- Dual Drive Options:Choose between hydraulic drive or dual electric motors with planetary gear reducers. Both options deliver powerful, stable shredding performance and wide adaptability to various panel sizes and materials.

Choose GEP ECOTECH for smart, efficient PV panel recycling solutions. If you have any inquiries, please feel free to contact us.